This training course is designed to provide participants with an in-depth knowledge of the technology and processes can be met on production platform. Specific problems associated with operation and trouble shooting. Integrity assurance in well head deck and production facilities will be analyzed.

By the end of this training course, participants will be able to:

Organizational Impact:

Organizations benefit tremendously when their engineers possess a high degree of data, information and knowledge gained in this course. They will be well prepared to make decisions for future action concerning a wise supervision using modern technology and good utilization of trained personnel on production platform.

Personal Impact:

This training course teaches the participants to:

This training course is primarily designed for:

This interactive training course includes the following training methodologies as a percentage of the total tuition hours:

Day One: Introduction, Definitions and the Platform Environment

Day Two: Operations and Monitoring

Day Three: Operation, Supervision & Safety

Day Four: Safety Process

Day Five: Process Automation & Control

BTS attendance certificate will be issued to all attendees completing minimum of 80% of the total course duration.

| Code | Date | Venue | Fees | Register |

|---|---|---|---|---|

| MI118-05 | 01-07-2024 | Indonesia | USD 5950 | |

| MI118-06 | 13-10-2024 | Dubai | USD 5450 |

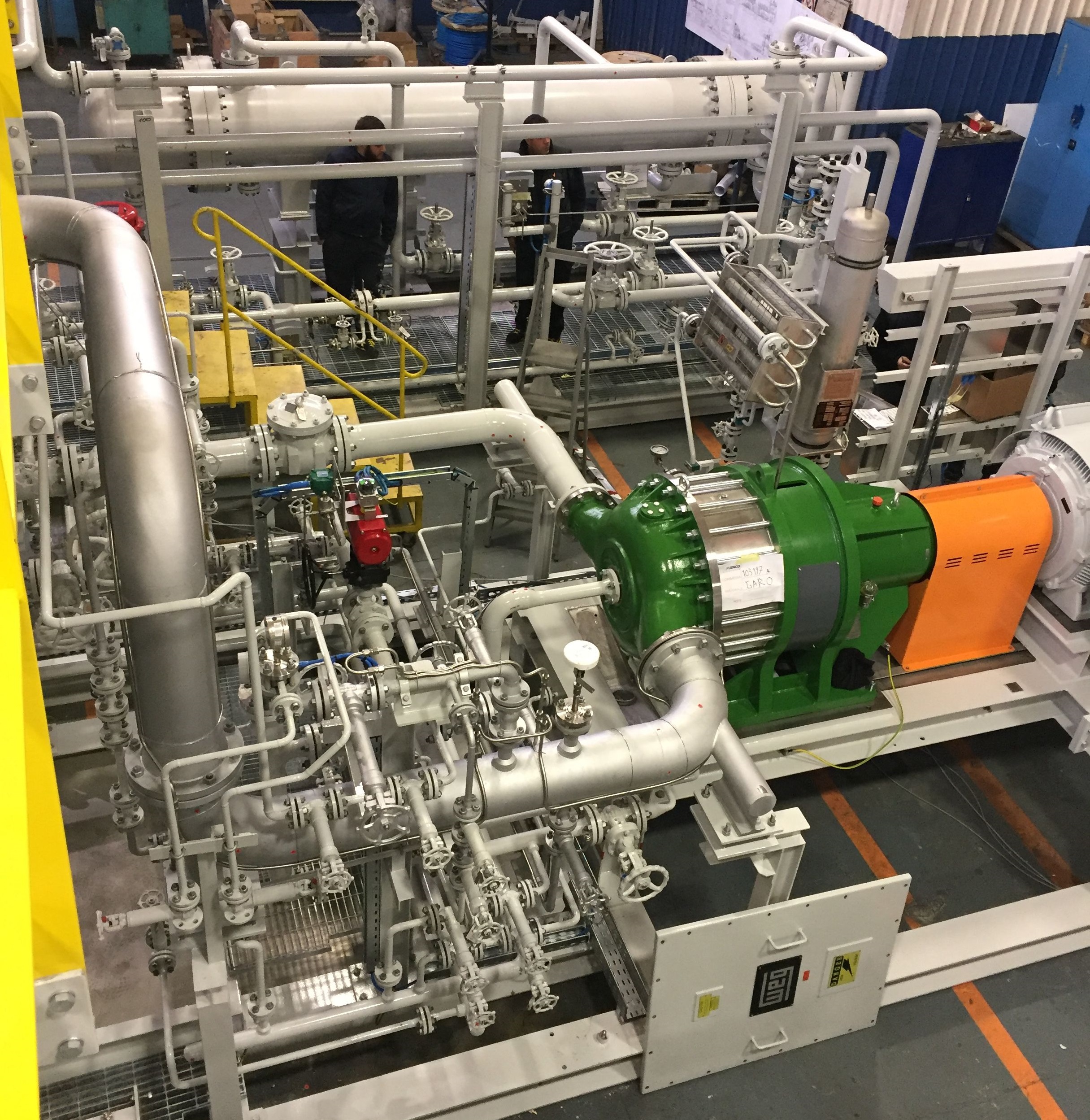

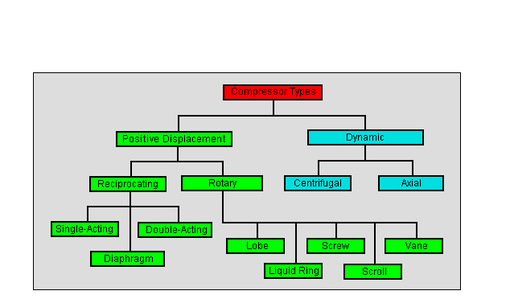

The course will introduce delegates to the various types of compressors and associated terminology. Centrifugal and positive-displacement compressors, packing, mechanical seals and sealing systems, be ...

This course will present the key activities involved in operation, control, maintenance and troubleshooting of gas compressors. These activities are vitally important for the efficient and safe operat ...

Upon completion of this course, participants will have gained a thorough understanding of the various centrifugal (i.e. turbo) and reciprocating compressor configurations available to virtually every ...

Centrifugal Compressors a play a very essential role in many petrochemical and industrial plants. Centrifugal compressors in general runs at very high speeds, exposed to high temperature. The compress ...

Providing services with a high quality that are satisfying the requirements

Appling the specifications and legalizations to ensure the quality of service.

Best utilization of resources for continually improving the business activities.

BTS keen to selects highly technical instructors based on professional field experience

Since BTS was established, it considered a training partner for world class oil & gas institution

1st floor, Incubator Buildingو Masdar City, Abu Dhabi, UAE

Sun to Fri 09:00 AM to 06:00 PM

Contact Us anytime!

Request Info