Course Details

Your Growth, Our Mission

Course Description

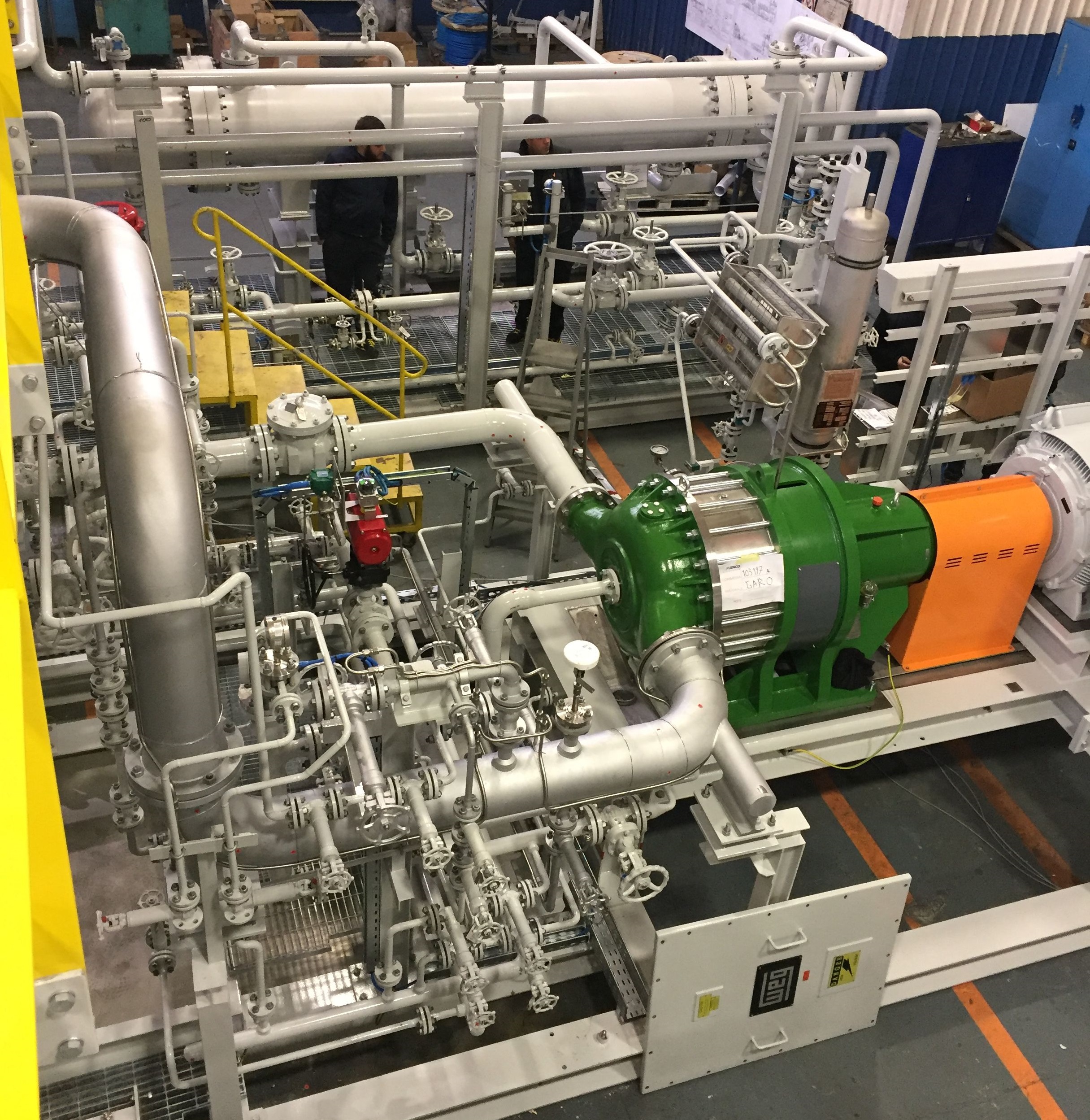

This course provides comprehensive training on the maintenance, operation, and performance monitoring of gas compressors which are vitally important for the efficient, reliable and safe operation of the plant. Participants will gain a deep understanding of the various types of gas compressors, their components, and the best practices for ensuring optimal performance and reliability. The course will also cover diagnostic techniques and preventive maintenance strategies, equipping attendees with the skills necessary to troubleshoot common issues and implement effective monitoring systems and condition monitoring techniques which are used as a technical approach to failure prevention. The course will also discuss vibration measurements and guidelines for preventive, predictive and corrective maintenance. Keeping compressor vibration under control makes a big impact on the long life of bearings, seals and other elements which improve compressor reliability and safety. The course will provide the best practices for various maintenance techniques including overhauling and repair. Problem solving and troubleshooting techniques as well as the methods for extending the lifetime of equipment will be discussed and explained.

The Training Course Will Highlight ?

Training Objective

Target Audience

- Maintenance Supervisors.

- Operations Supervisors, Plant Engineers and Process Engineers.

- Equipment Engineers Team Leaders and Professionals in Maintenance, Engineering and Production.

- Reliability and Maintenance Engineers.

- Senior Technicians, Senior Operators.

- Asset owners & Asset Managers and anyone who is interested to increase the knowledge about compressors.

Training Methods

This interactive Training will be highly interactive, with opportunities to advance your opinions and ideas and will include:

- Lectures

- Workshop & Work Presentation

- Case Studies and Practical Exercise

- Videos and General Discussions

- pre and post assessments

Daily Agenda

Module 1: Introduction to Gas Compressors

- Overview of gas compression principles

- Types of gas compressors (reciprocating, rotary, centrifugal)

- Applications and industries utilizing gas compressors

Module 2: Compressor Components and Operation

- Key components of gas compressors

- Working principles of different compressor types

- Understanding pressure, temperature, and flow dynamics

Module 3: Key Operating Parameters and Controls:

- Overview of operational characteristics of process gas compressors

- Understanding key operating parameters of gas compressors

- Control systems and their role in maintaining optimal operation

- Control strategies for efficiency and safety

Module 4: Compressor Performance

- Performance curves

- Performance curves-operating point

- Performance curves-operating range

- Performance curves-system resistance curve

- Compressor regulation

- Compressor regulation-process control methods

Module 5: Abnormal Condition and Troubleshooting:

- Identifying abnormal conditions in gas compression operations

- Off design conditions

- Abnormal operating conditions

- Abnormal operating conditions-Choking

- Abnormal operating conditions-Rotating stall

- Abnormal operating conditions- Surge

- Anti-surge protection system

Module 6: Monitoring and Performance Evaluation

- Monitoring of compressor operation and performance parameters

- Techniques for monitoring compressor performance

- Key performance indicators (KPIs) for gas compressors

Module 7: Maintenance Strategies

- Importance of preventive maintenance

- Routine maintenance tasks and schedules

- Lubrication systems and their significance

- Tools and equipment for maintenance

Module 8: Troubleshooting Common Issues

- Identifying symptoms of compressor problem

- Diagnostic techniques for operational issues

- Typical problems in operation of centrifugal and axial compressors

- Methods for surge prevention

- Typical problems in operation of screw compressors.

- Typical problems in operation of reciprocating compressors

- Case studies of common failures and solutions

Module 9: Compressor condition monitoring system

- Vibration monitoring and control measurements

- Vibration root cause analysis

- Bearing failures and lubricant oil analysis

- Mechanical seal and dry seal maintenance

- Preventive, predictive and corrective maintenance: scope & procedure

- Inspection of most critical parts

- Leak control and prevention

- Problem detection and diagnostics: root cause analysis

- Troubleshooting procedures in normal and abnormal conditions

- Overhaul and repair options

Module 10: Practical Applications and Case Studies

- Compressors control systems and instrumentation

- Compressor protection and safety system

- Real-world case studies to reinforce learning

- Group discussions and knowledge sharing

Accreditation

BTS attendance certificate will be issued to all attendees completing minimum of 80% of the total course duration.

Quick Enquiry

Request Info

Related Courses

Your Growth, Our Mission