This course is developed for engineers and technicians who need to have a practical knowledge of selection, installation and commissioning of fiscal metering equipment. It is for those primarily involved in achieving effective results in industrial processes. This would involve the design, specification and implementation of control and measurement equipment. The course focuses on practical applications, with special attention to installation considerations and application limitations when selecting or installing different measurement or control instruments for fiscal metering.

By the end of this BTS training course, participants will be able to:

MGC Coordinators and Supervisors, Instrumentation & Metering Engineers & Technicians, Metering Managers and Engineers, Production Operation & Process Engineers, Instrument Workshop Supervisors, Production Technologists, Design & Mechanical Engineers, Service Staff and Inspectors of Custody Transfer Stations, Design & Process Engineers, Reservoir Engineering & Custody Technicians, Well Testing Group & Chemical Engineers, Valve Technicians & Maintenance Personnel & Supervisors

This interactive Training will be highly interactive, with opportunities to advance your opinions and ideas and will include;

Introduction to Fundamentals of Measurement & Basic Fluid Flow

Performance Characteristic of Flow meter

Custody Transfer Applications

Head Flow Meter

Ultrasonic Flow meter

Oil Transfer Meter

Shipping Calculate Volume & Calculate Correction

Retroactive Meter Factor

Calculation Sample

BTS attendance certificate will be issued to all attendees completing minimum of 80% of the total course duration.

| Code | Date | Venue | Fees | Register |

|---|---|---|---|---|

| DE148-01 | 02-02-2025 | Dubai | USD 5450 | |

| DE148-02 | 21-04-2025 | Kuala-Lumpur | USD 5950 | |

| DE148-03 | 14-09-2025 | Dubai | USD 5450 | |

| DE148-04 | 08-12-2025 | Istanbul | USD 5950 |

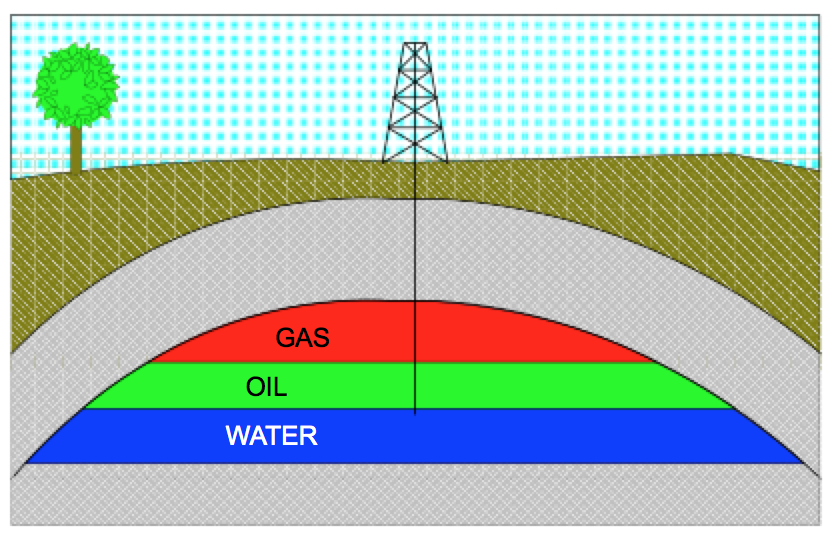

Hydrocarbon systems found in petroleum reservoirs are known to display multi-phase behavior over wide ranges of pressure and temperatures. The most important phases that occur in petroleum reservoirs ...

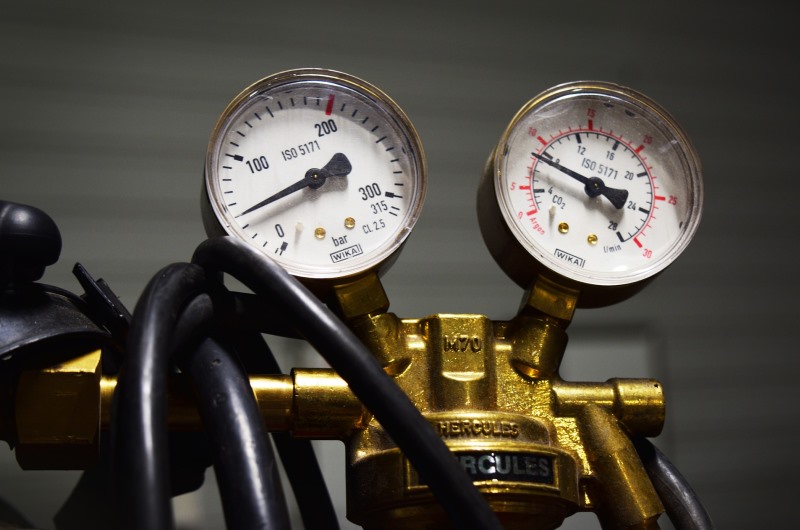

A Custody Transfer Metering Operations course typically focuses on the principles, technologies, and procedures involved in the accurate measurement of fluids (such as oil, gas, or chemicals) during t ...

This course aims to provide participants with the knowledge and practical skills needed to operate and maintain custody transfer metering systems, with a focus on accuracy, standards, calibration, and ...

The Flow Measurement and Custody Transfer training course is designed to provide comprehensive knowledge and practical skills for professionals involved in the measurement and transfer of fluid (liq ...

Providing services with a high quality that are satisfying the requirements

Appling the specifications and legalizations to ensure the quality of service.

Best utilization of resources for continually improving the business activities.

BTS keen to selects highly technical instructors based on professional field experience

Since BTS was established, it considered a training partner for world class oil & gas institution

1st floor, Incubator Buildingو Masdar City, Abu Dhabi, UAE

Sun to Fri 09:00 AM to 06:00 PM

Contact Us anytime!

Request Info