By the end of this training course, participants should be able to:

• This course provides an introduction and overview of the most significant aspects and considerations of process risk management and its relationship to process safety.

• It is designed to help participants understand the concepts, criteria, and methodologies of risk management, and to apply them at a practical level in the design, engineering, and operation of facilities.

• It will enable participants to analyze the significance of potential process hazards, make initial recommendations to eliminate or reduce those hazards, reduce the consequences of potential process accidents, and to improve the overall safety level of an existing project or facility.

This course is designed to provide valuable knowledge to the following professionals:

• Management and supervisory personnel involved in routine decision making on the management, engineering, safety, maintenance, and operation of process facilities in the Oil/ Gas industry.

• Managers, supervisors, design engineers, project engineers, operations, and maintenance personnel, PSM and HSE personnel, as well as instrumentation, automation and control engineers.

• Any other professional wishing to gain a better understanding of the subject.

A variety of methodologies will be used during the course that includes:

• 30% Based on Case Studies

• 30% Techniques

• 30% Role Play

• 10% Concepts

• Variety of Learning Methods

• Lectures

Day 1

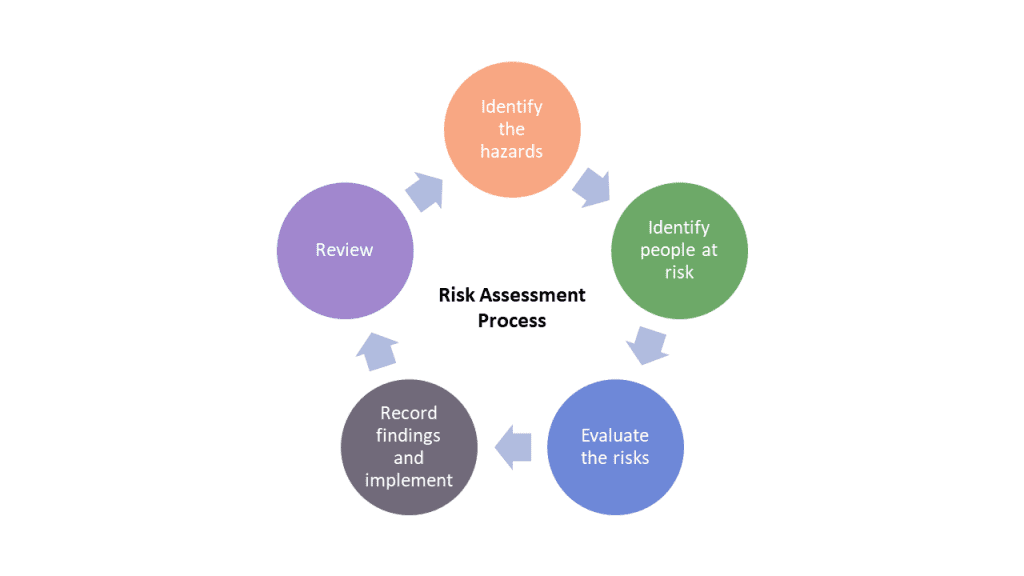

- Risk Management Process

- Risk Management Process Requirements

- Effectiveness of Risk Management Program

- Continuous Improvement

Day 2

- Hazards Identification and screening

Day 3

- Risk Analysis:

Qualitative Methods

Semi-Quantitative Methods

Quantitative Methods

Risk Matrix as per KPC guidelines

Day 4

- Critical Decisions

- Fundamental Principles

- Reasonably practicable:

Manifestly Disproportionate

Uncertainty and the Precautionary Principle

Risk Aversion

Good Practice vs. Best Practice

Day 5

✓ Quantitative

✓ Qualitative

✓ Risk Tolerability Criteria

✓ Cost-Benefit Analysis (CBA)

BTS attendance certificate will be issued to all attendees completing minimum of 80% of the total course duration.

| Code | Date | Venue | Fees | Register |

|---|---|---|---|---|

| HSE212-01 | 05-04-2026 | Dubai | USD 5450 | |

| HSE212-02 | 20-07-2026 | Istanbul | USD 5950 | |

| HSE212-03 | 25-10-2026 | Cairo | USD 5450 | |

| HSE212-04 | 20-12-2026 | Manama | USD 5450 |

.jpg)

This course will assist companies to reduce risk and avoid losses reducing from the unintended releases of toxic, reactive, or flammable liquids and gases in processes involving highly hazardous mater ...

The global trend in integrating Health, Safety and Environmental Management Systems underpins commitment to implementing a pro-active approach to risk management based on structured and systematic ris ...

Introduction: Traditional’ risk assessment programs exist to identify hazards arising from work activities to ensure suitable risk control measures are in place. However, incidents continue to happen ...

When it is required identify and quantify hazards and potential accident scenarios associated with hazardous processes, it may be necessary to conduct a process risk analysis. Conducting this analysis ...

Providing services with a high quality that are satisfying the requirements

Appling the specifications and legalizations to ensure the quality of service.

Best utilization of resources for continually improving the business activities.

BTS keen to selects highly technical instructors based on professional field experience

Since BTS was established, it considered a training partner for world class oil & gas institution

1st floor, Incubator Buildingو Masdar City, Abu Dhabi, UAE

Sun to Fri 09:00 AM to 06:00 PM

Contact Us anytime!

Request Info