The course objectives include:

Day 1 Overview of Process Risk Analysis approach

Day 2 Hazard spotting -- Identifying Vulnerable Sections of a plant Use of Hazard Identification Techniques

Day 3 Reliability Analysis for Instrument and Human failures

Day 4 Quantification of Risk -- Employing HAZAN technique

Day 5 Process Safety Management

BTS attendance certificate will be issued to all attendees completing minimum of 75% of the total course duration.

| Code | Date | Venue | Fees | Register |

|---|---|---|---|---|

| HSE210-01 | 26-04-2026 | Cairo | USD 5450 | |

| HSE210-02 | 05-07-2026 | Amman | USD 5450 | |

| HSE210-03 | 07-09-2026 | Istanbul | USD 5950 | |

| HSE210-04 | 29-11-2026 | Dubai | USD 5450 |

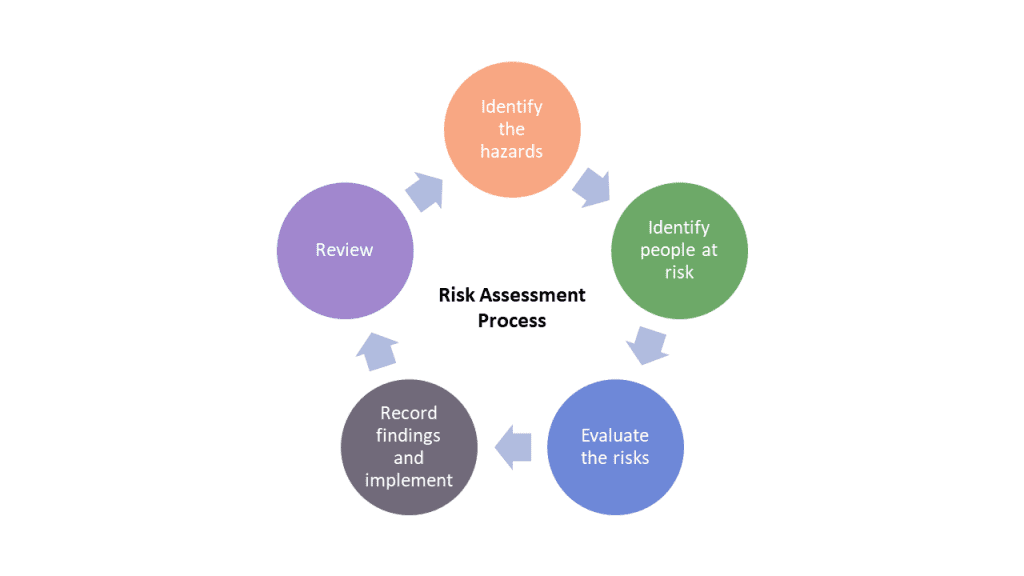

The global trend in integrating Health, Safety and Environmental Management Systems underpins commitment to implementing a pro-active approach to risk management based on structured and systematic ris ...

Introduction: Traditional’ risk assessment programs exist to identify hazards arising from work activities to ensure suitable risk control measures are in place. However, incidents continue to happen ...

The global trend to implement process safety management (PSM) systems underpins the commitment to implement a proactive approach to process risk management, based on a structured and systematic risk m ...

.jpg)

This course will assist companies to reduce risk and avoid losses reducing from the unintended releases of toxic, reactive, or flammable liquids and gases in processes involving highly hazardous mater ...

Providing services with a high quality that are satisfying the requirements

Appling the specifications and legalizations to ensure the quality of service.

Best utilization of resources for continually improving the business activities.

BTS keen to selects highly technical instructors based on professional field experience

Since BTS was established, it considered a training partner for world class oil & gas institution

1st floor, Incubator Buildingو Masdar City, Abu Dhabi, UAE

Sun to Fri 09:00 AM to 06:00 PM

Contact Us anytime!

Request Info