Course Details

Your Growth, Our Mission

Course Description

The Training Course Will Highlight ?

Training Objective

Target Audience

- Professionals dealing with the operation and maintenance of rotating equipment

- New technicians who wish to improve knowledge and skills

- Those who are involved in condition monitoring and vibration analysis

- Maintenance technicians who are in charge of correcting the machinery problems

- Engineers and maintenance planners involved in machine’s condition monitoring

Training Methods

This training course will be conducted along workshop principles with formal lectures and interactive examples, which will result in the active participation of all delegates in discussions and teamwork of problem solving. Real life examples will be selected to be solved during several workshop in the form of team work which will enable understanding of the physical insight of the problems and will illustrate the efficient application of evaluation tools. There will be ample opportunities for active, open discussions and sharing professional experiences on various industrial applications. All training course materials will be provided.

Daily Agenda

Couplings: Types, Application & Operation

- Classification & Application of Couplings

- Characteristics of Rigid Couplings

- Characteristics of Flexible Couplings

- Selection of Parameters of Couplings for Pumps & Compressors and Turbines

- Advantages & Disadvantages of Different Types

Couplings: Installation, Maintenance & Troubleshooting

- Installation Best Practices & Safety Issues

- Coupling Inspection in Operation

- Vibration Monitoring and Analysis

- Preventive Maintenance & Condition Monitoring

- Failure Prevention & Troubleshooting

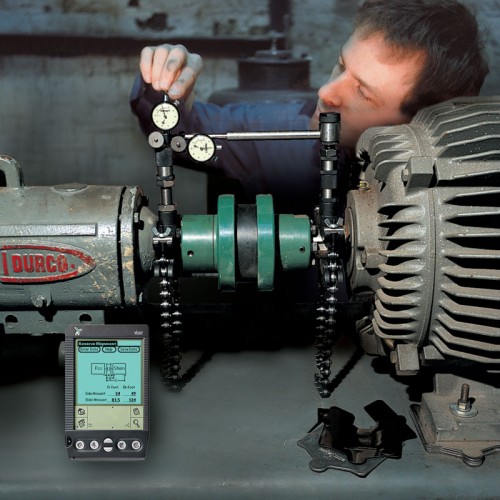

Shaft Alignment Basics

- Need for Shaft Alignment

- Effects of Shaft Misalignment

- Types of Misalignment: Offset and Angularity

- Measuring Techniques

- Rim and Face Alignment Method: TIR Determination

Alignment Measurement Methods

- Reverse Dial Methodology

- Correcting Misalignment: Foundation and Soft Foot

- Thermal Growth Determination

- Laser Optic Technique

- Misalignment Detected by Vibration Monitoring

Effect of Misalignment on Bearings & Seals

- Effect of Misalignment of Bearings

- Vibration Monitoring Results as Indication of Misalignment

- Effect of Misalignment on Seals of Pumps and Compressors

- Leakage Control & Prevention

- Summary and Conclusions

Accreditation

BTS attendance certificate will be issued to all attendees completing minimum of 80% of the total course duration.

Quick Enquiry

Request Info

Related Courses

Your Growth, Our Mission