Course Details

Your Growth, Our Mission

Course Description

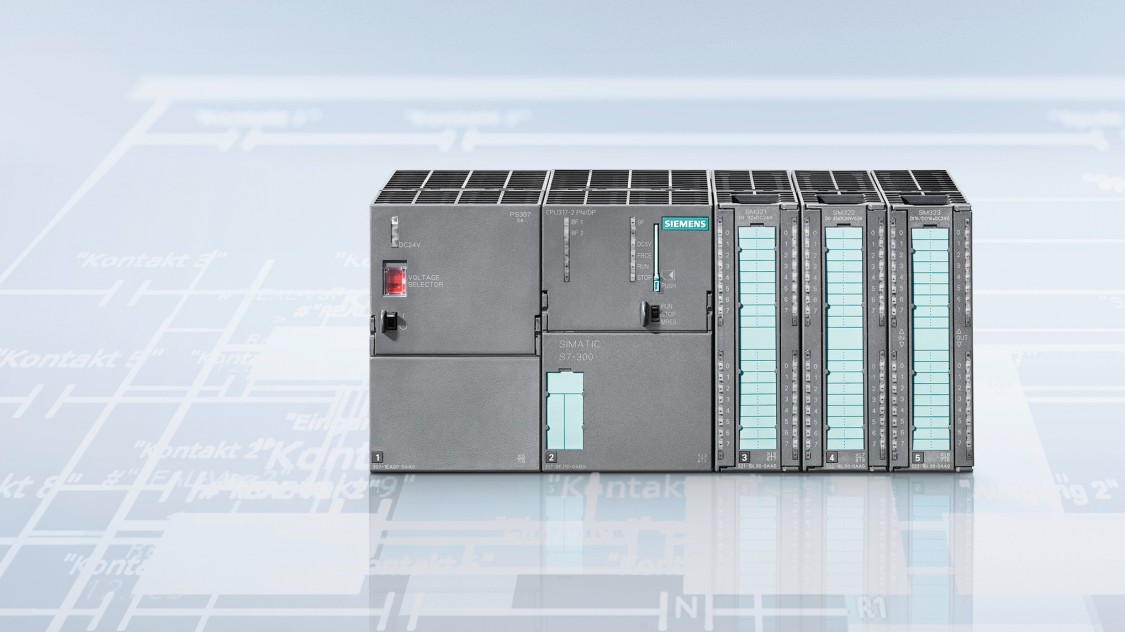

This 5 days course is designed to benefit the participants with practical up-to-date information on the application of PLC's to the automation and process control of plants and factories. It is introducing the configuration & troubleshooting aspects of Siemens PLC S7 series. It aims to give practical advice from experts in the field, to assist correctly plan, programme and install a PLC with a shorter learning curve and more confidence.

While this course is ideal for engineers who are new to PLCs, much of the contents and additional material in the extensive manual will be of value to those who already have the basic skills, but need a wider perspective for larger and more challenging tasks ahead.

The information contained in this course advances from the basics to challenge even the most experienced engineer in the industry today.

The course is supported by Video demonstrating PLC Programming techniques.

The Training Course Will Highlight ?

Training Objective

Target Audience

This course is designed for:

- New engineers / tech.

- Senior engineers / tech.

- Process engineers / tech.

- Instrumentation engineers / tech.

- Electrical engineers / tech.

Training Methods

Practical/Theoretical Sessions:

- Practical 65% (through software simulators)

- Theoretical 35%

Daily Agenda

Day one:

Chapter 1: INTRODUCTION TO PROGRAMMABLE CONTROLLERS

- Introduction to Siemens PLC400 and PLC history.

- PLC types and vendors.

- PLC Siemens S7-300& 400 hardware components.

- Power supply modules specs and wiring.

- CPU modules specs and installation.

- Digital modules types and wiring.

- Binary and digital operations

Day Two:

- Analog modules types.

- Introduction to communication modules.

- Basic components of Siemens S7 software (programming and configuration environment).

- Hardware configuration and addressing.

- Case studies

Day Three:

- PLC programming basics.

- Ladder programming (logic instructions).

- Timers, counters , Arithmetic operations,...

- Symbols in PLC program.

- Integrating FCs and FBs

- Case studies

Day Four:

- PLC application organization.

- Using simulator.

- Download and debug applications.

- Dealing with data blocks and local variables.

- Tracing a Siemens S7 PLC program and troubleshooting .

- Logic instructions complete application example.

- Arithmetic instructions complete application example.

- Case studies

Day Five:

- Create a link between Wincc scada program

- Troubleshooting and configuration the scada and PLC

- Case studies

Accreditation

Quick Enquiry

Request Info

Related Courses

Your Growth, Our Mission