Course Details

Your Growth, Our Mission

Course Description

The Training Course Will Highlight ?

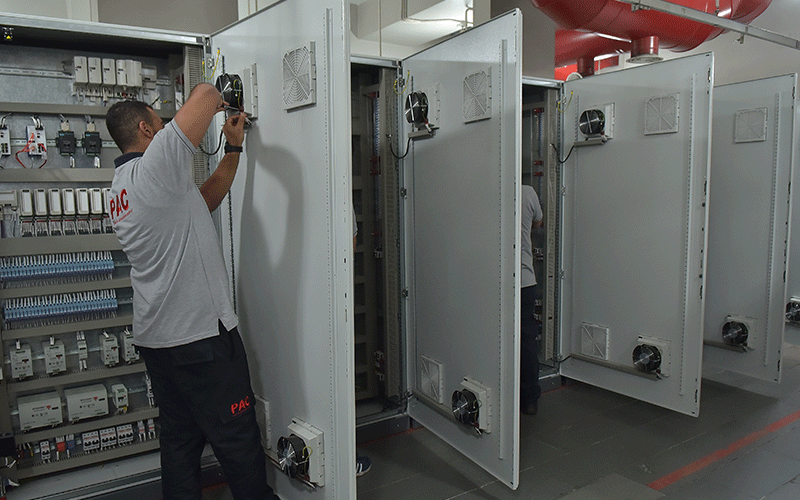

This course is designed to benefit you with practical up-to-date information on the application of PLC's and SCADA to the automation and process control of plants and factories. It is suitable for people who have little or no exposure to PLC and SCADA but expect to become involved in so m e or all aspects of PLC installation and SCADA Programming. It aims to give practical advice from experts in the field, to assist you to correctly plan, program m and install a PLC with a shorter learning curve and more confidence.

Training Objective

This course is designed to benefit you with practical up-to-date information on the application of PLC's and SCADA to the automation and process control of plants and factories. It is suitable for people who have little or no exposure to PLC and SCADA but expect to become involved in so m e or all aspects of PLC installation and SCADA Programming. It aims to give practical advice from experts in the field, to assist you to correctly plan, program m and install a PLC with a shorter learning curve and more confidence.

Target Audience

Electrical Engineers, Electrical Technicians, Electrical Inspectors, Electrical Professionals & Supervisors, Instrumentation and Design Engineers, Maintenance Engineers, Supervisors & Technicians, Energy Management Consultants, Control Engineers & Technicians, Automation & Process Engineers, Chemical & Mechanical Engineers, Consulting Engineers, Field Technicians, Graduate Engineers, Project and Production Managers, Project Engineers, Electronic Technicians, Plant Managers, Process Control Engineers, System Engineers, System Integrators, Testing Engineers & Technicians, Power System Engineers, Power System Technicians, Utility Engineers, Managers & Team Leaders of Engineering Departments, Safety Professionals, Plant Electricians, Facilities Engineers, Operations & Maintenance Engineers, Supervisors & Technicians, Project Engineers, Commissioning & Testing Engineers, Consulting Engineers, Electrical Technologists, Facility & Plant Managers, IT Personnel

Training Methods

This interactive Training will be highly interactive, with opportunities to advance your opinions and ideas and will include;

- Lectures

- Workshop & Work Presentation

- Case Studies and Practical Exercise

- Videos and General Discussions

Daily Agenda

Basic Components of PLC

- Fundamentals principles

- CPU

- Memory

- I/O section and addressing

- Digital I/O modules

- Analog I/O modules

PLC Programming

- Ladder logic instructions

- Basic arithmetic instructions

- Matrix logic

- File or block manipulation

- Jump, skips and subroutines

- PLC instruction sets

- Memory organization

- Input/output addressing

- Duplicate coils

- Timers

Installation Practices

- Interference or noise reduction

- Cable spacing and routing

- Earthing and grounding

- Safety circuits

- Control room requirements and layout

Code Quality and Maintenance

- Program maintenance

- Change procedures

- Defect detection

- Quality measurement and demonstration

Advanced Programming

- Matrix logic

- Multiplexing

- Coding/decoding

Analog Control

- Analog inputs

- Signal filtering

- Analog control

Fault Tolerance

- Improving system availability

- Hot standby systems

- Cold standby

Serial Data Communications

- RS-232/485 Standards

- Modbus Protocol

- Local Area Networks

- Ethernet

- Token Bus

Safety Related Systems

- Safety lifecycle

- Systematic failures/rates

- Voting systems

- Software reliability

- Field equipment

Upgrading Strategies

Simulation and Testing

- Factory acceptance testing (FAT)

- Transport and reassembly

- Simulation packages

- Physical test panels

- I/O emulation systems

Problem Isolation and Testing

SCADA Hardware

- Field level Instrumentation and control

- Marshalling terminals and RTUs

- Communication System

- Master Stations

SCADA Software

- Communications protocol

- Data objects

- Interchangeability

- Proprietary systems

Accreditation

BTS attendance certificate will be issued to all attendees completing minimum of 80% of the total course duration.

Quick Enquiry

Request Info

Related Courses

Your Growth, Our Mission