Course Details

Your Growth, Our Mission

Course Description

The Training Course Will Highlight ?

The prediction of reservoir souring requires assessment of three key factors:

- Microbial generation of H 2S

- Transport and scavenging of microbial generated H 2S in the reservoir

- Partitioning of H 2S between the oil, gas and water phases.

Generic computer-based predictive models currently exist which, although based on the same fundamental principles, take different approaches to assessing the level of H 2S generation. Each model has its own strengths and weaknesses.

Training Objective

The prediction of reservoir souring requires assessment of three key factors:

- Microbial generation of H 2S

- Transport and scavenging of microbial generated H 2S in the reservoir

- Partitioning of H 2S between the oil, gas and water phases.

Generic computer-based predictive models currently exist which, although based on the same fundamental principles, take different approaches to assessing the level of H 2S generation. Each model has its own strengths and weaknesses.

Target Audience

Training Methods

This interactive Training will be highly interactive, with opportunities to advance your opinions and ideas and will include;

- Lectures

- Workshop & Work Presentation

- Case Studies and Practical Exercise

- Videos and General Discussions

Daily Agenda

Chapter 1: Introduction

1.1 Reservoir Souring

2.1 Microbial Reservoir Souring

2.1.1 Sulfate‐Reducing Bacteria

2.1.2 Souring Mechanism

2.1.3 H 2 S Transport

2.2 Reservoir Souring Remediation Methods

2.2.1 Sulfate Nano‐Filtration

2.2.2 Biocides

2.2.3 Nitrate Injection

2.2.3.1 Experiments for Reservoir Souring Remediation by Nitrate.

2.2.3.2 Field Application of Nitrate Injection

2.3 Modeling of Reservoir Souring

2.3.1 Mixing Model

2.3.2. Biofilm Model

2.3.3 Thermal Viability Shell (TVS) Model

2.3.4 Mechanistic Model of Burger et al. (2005

2.3.5 Reservoir Souring Simulators

2.3.6 Reservoir Souring Simulation with UTCHEM

Chapter 3: General Purpose Adaptive Simulator (GPAS)

3.1 Overview of GPAS

3.2 Framework

3.3 EOS Compositional Module

3.4 Chemical Compositional Module

3.4.1 Governing Equations

3.4.1.1 Material Balance Equations

3.4.1.2 Volume Constraint Equation

3.4.2 Fully‐Implicit Solution Procedure

3.5 Corner Point Formulation

3.6 Parallel Processing

Chapter 4: Implementation of the Biological Model in GPAS

4.1 Overview of Biological Model

4.1.1 Product Generation, Nutrition, and Inhibition Effects

4.1.2 Solving the Biological Model Equations

4.2 Modeling Nitrate Inhibition Mechanisms

4.2.1 Inhibitory Action of Nitrite

4.2.2 Bio‐Competitive Exclusion

4.2.3 Nitrate Utilization by SRB

4.2.4 Nitrate‐Reducing Sulfide‐Oxidizing Bacteria Stimulation

4.3 Implementation in GPAS

4.3.1 Solution of the Combined Transport and Biological Equations.

4.3.2 GPAS Biological Model Code

Chapter 5: Model Verification with Experimental Data

5.1Microbial Souring in Porous Media

5.2 Control of Microbial Souring by Nitrate

5.3 NR‐SOB Activity in a Batch Reactor

5.4 NR‐SOB Activity in a Column

Chapter 6: Effect of Dispersion on Reservoir Souring

6.1 Dispersion in Porous Media

6.1.1 Molecular Diffusion and Mechanical Dispersion

6.1.2 Convection Diffusion Equation (CDE)

6.2 Investigation of Dispersion Effects by UTCHEM

6.2.1 One‐Dimensional Homogeneous Reservoir

6.2.2 Three‐Dimensional Heterogeneous Reservoir Model

6.2.2.1 Seawater Injection (SWI)

6.2.2.2 Produced Water Re‐Injection (PWRI)

6.2.2.3 Effect of Heterogeneity

Chapter 7: Physical Dispersion Model in GPAS

7.1 Full Tensor Formulation in GPAS

7.2 Semi‐Implicit Implementation

7.3 Physical Dispersion Model Verification

7.3.1 Validation with One‐Dimensional Analytical Solution

7.3.2 Comparison of Two‐Dimensional Simulations with UTCHEM .

7.3.3 Non‐Orthogonal Grid

7.4 Investigation of Numerical Dispersion in GPAS

7.4.1 Truncation Error Analysis

7.4.2 Gridblock Size Effect

7.4.3 Time Step Effect

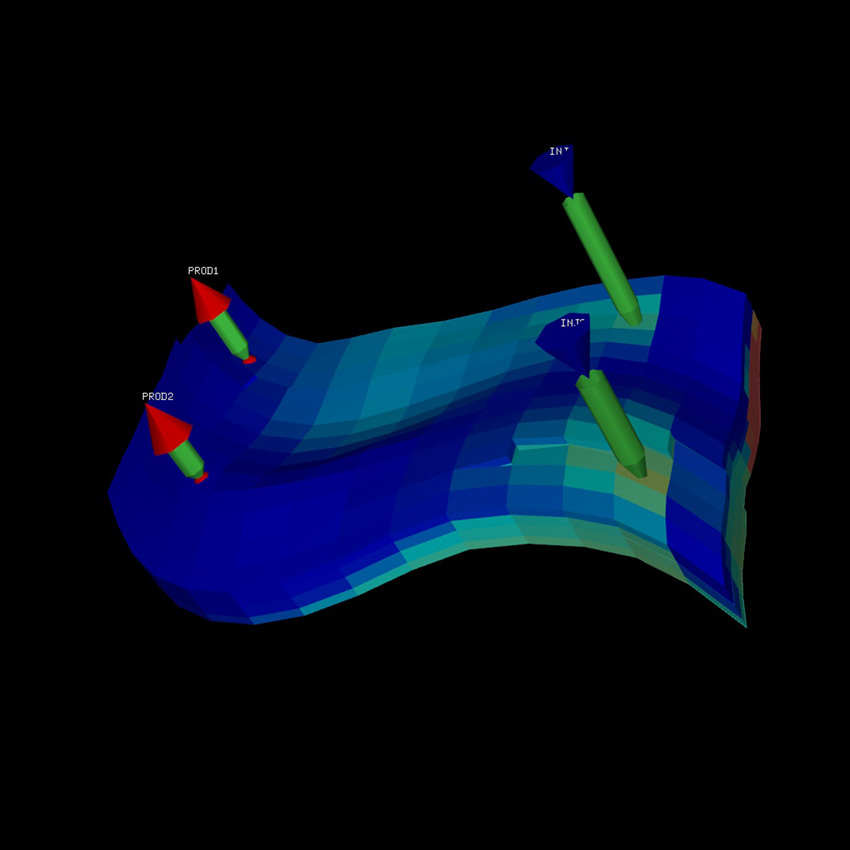

Chapter 8: Field Application of GPAS Reservoir Souring Model

8.1 Non‐Orthogonal Reservoir Model

8.1.1 Souring without Nitrate Injection

8.1.2 Nitrate Injection after H 2 S Breakthrough

8.1.3 Initial Nitrate Injection

8.2 Parallel Processing

8.2.1 Model

8.2.3 Multi‐Processor Runs

8.2.4 Grid Refinement

Accreditation

BTS attendance certificate will be issued to all attendees completing minimum of 80% of the total course duration.

Quick Enquiry

Request Info

Related Courses

Your Growth, Our Mission