At the end of this industrial hygiene course, the target competencies will be able to:

This interactive Training will be highly interactive, with opportunities to advance your opinions and ideas and will include:

Day 1: Introduction to Industrial Hygiene

Day 2: Exposure Assessment and Monitoring

Exposure Limits and Standards:

Day 3: Toxicology and Health Effects

· Health Effects of Hazardous Exposures:

Day 4: Hazard Control Strategies

· Hierarchy of Controls:

· Emergency Response Planning:

· Case Study: Implementing Controls in an Industrial Setting:

Day 5: Program Management and Regulatory Compliance

· Managing an Industrial Hygiene Program:

· Health and Safety Audits:

· Regulatory Compliance:

· Final Project and Course Review:

BTS attendance certificate will be issued to all attendees completing minimum of 80% of the total course duration.

| Code | Date | Venue | Fees | Register |

|---|---|---|---|---|

| HSE220-01 | 03-05-2026 | Dubai | USD 5450 | |

| HSE220-02 | 27-07-2026 | Istanbul | USD 5950 | |

| HSE220-03 | 11-10-2026 | Cairo | USD 5450 | |

| HSE220-04 | 06-12-2026 | Manama | USD 5450 |

Occupational Risk Management is a modern fast moving subject. It covers all aspects of risk associated with the worker, the work environment and its effects on health. There are many interfaces with o ...

Industrial hygiene can be defined as the art and science devoted to the anticipation recognition, evaluation, communication and control of environmental stressors in the work place that may result in ...

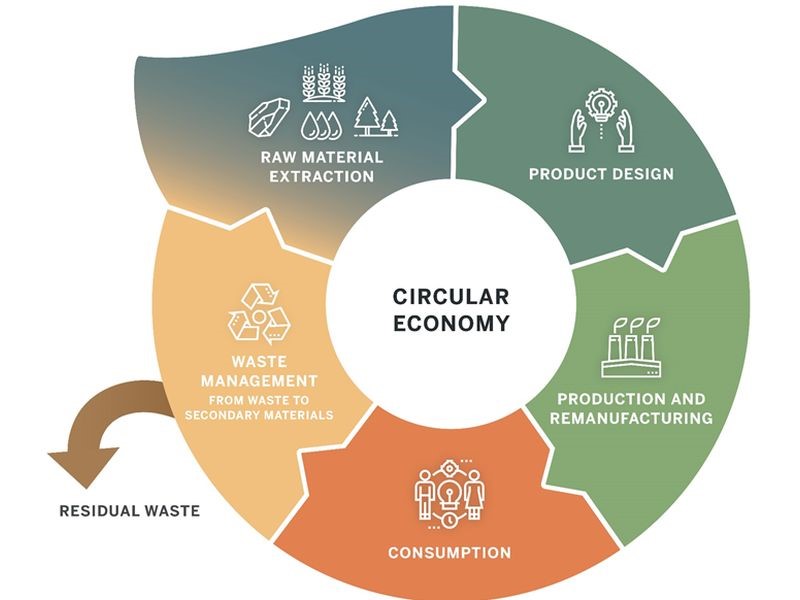

Global consumption patterns with increasing complexity and volume of generated waste, urge for the need to continuously optimize waste management. The driving force behind this mobilization is primari ...

Occupational Risk Management is a modern fast moving subject. It covers all aspects of risk associated with the worker, the work environment and its effects on health. There are many interfaces with o ...

Providing services with a high quality that are satisfying the requirements

Appling the specifications and legalizations to ensure the quality of service.

Best utilization of resources for continually improving the business activities.

BTS keen to selects highly technical instructors based on professional field experience

Since BTS was established, it considered a training partner for world class oil & gas institution

1st floor, Incubator Buildingو Masdar City, Abu Dhabi, UAE

Sun to Fri 09:00 AM to 06:00 PM

Contact Us anytime!

Request Info