Key Benefits:

Organizational Impact:

Predictive maintenance of rotating plant is vital to the budgetary success of the operations organisation. On completion of this seminar the delegate will be able to critically analyse the methodologies employed within the organisation and instigate improvements where required.

Personal Impact:

Technical knowledge is key to effective control and peer respect within any maintenance organisation; when this is achieved personal satisfaction follows. This seminar will give the delegate the required level of technical knowledge and skill to achieve that personal satisfaction.

Competencies:

At the end of this seminar participants will have:

This seminar is directed towards Supervisors, Team Leaders and Managers in Maintenance , Engineering and Production . The seminar will also benefit anyone who wishes to update themselves on Centrifugal Compressors and Steam Turbines, judge the suitability of them for their needs, and learn how to operate and maintain them for the benefit of their organisations.

The seminar will be conducted along workshop principles with formal lectures, case studies and interactive worked examples. Relevant case studies will be provided to illustrate the application of each tool in an operations environment. Each learning point will be re-enforced with practical exercises. There will be ample opportunities for discussion and sharing experiences.

Day 1 - Gas Laws & Compression Theory

Compression and Expansion Fundamentals

Compression and Expansion Mechanisms

Day 2 – Practical Applications

Compressor and Turbine Performance and Operation

Day 3 – Steam Plant & Turbines

Steam turbines

Day 4 - Turbine Construction & Maintenance

Construction and Systems

Day 5 – Engineering Aspects

BTS attendance certificate will be issued to all attendees completing minimum of 80% of the total course duration.

| Code | Date | Venue | Fees | Register |

|---|---|---|---|---|

| ME141-02 | 17-05-2026 | Amman | USD 5450 | |

| ME141-03 | 24-08-2026 | Istanbul | USD 5950 | |

| ME141-04 | 15-11-2026 | Dubai | USD 5450 |

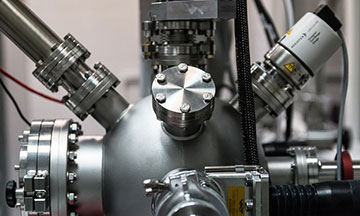

Centrifugal Compressors a play a very essential role in many petrochemical and industrial plants. Centrifugal compressors in general runs at very high speeds, exposed to high temperature. The compress ...

Providing services with a high quality that are satisfying the requirements

Appling the specifications and legalizations to ensure the quality of service.

Best utilization of resources for continually improving the business activities.

BTS keen to selects highly technical instructors based on professional field experience

Since BTS was established, it considered a training partner for world class oil & gas institution

1st floor, Incubator Buildingو Masdar City, Abu Dhabi, UAE

Sun to Fri 09:00 AM to 06:00 PM

Contact Us anytime!

Request Info