• Familiarize participant of different compressors design.

• Learn how different design parameter affects the machines performance and operation.

• Familiarize participant of the different types of gas compressors and their application

• To deepen the participants understanding of the limits of the compressor operation.

• Enable participants to read and calculate the performance curves of compressor

• To familiarize the participant with control, and protection systems of centrifugal compressor systems.

• To familiarize the participant to start and shut down the compressor in smooth and properly methods.

Engineers and Technicians operation, mechanical, reliability electrical and instrument working on turbomachinery, turbines and compressors are the ones to attend this course.

This interactive Training will be highly interactive, with opportunities to advance your opinions and ideas and will include:

The Following Topics will be covered in this course over five days Outlines:

Day 1

Day 2

A-Types of Turbo machinery

B-Centrifugal compressors types

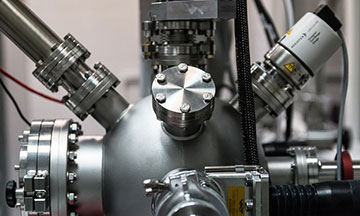

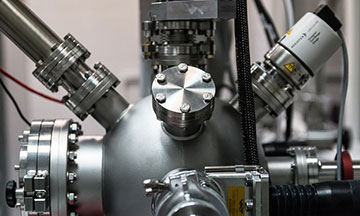

C-Centrifugal compressors components

D-The operation theory of centrifugal compressors

E-Compressor auxiliaries

F- Surge and antisurge system

G-video move about the centrifugal compressors component

Day 3

Centrifugal Compressors operation

A- Relationship between compressor and system curves.

B- Compressor behavior in common applications.

Degradation of Compressor Performance

Causes of Performance Variation

Load Sharing

video move for centrifugal compressor operation

Day 4

On-line performance monitoring system

Parameters Affecting the Compressor Performance

Features of Surge Control Systems:

Surge Control Operation (set Point Location)

Set Point Shift

Compressors Operation Problems

Compressors operation (start up and shutdown )

Start / stop logic tree for centrifugal compressor

Practical training on interactive compressors training program

Day 5

1-Dry seal gas

2-Troubleshooting and Maintenance

Non Destructive Inspection

Troubleshooting

3-Prédictive vs. Préventive Maintenance Techniques:

Case Studies & Discussions, Last Day Review will be carried out.

The support tools four video movie about the principle and maintenance oF the centrifugal compressors.

Note: The Course Manual will be as WinWord documents or acrobat reader (hand made according to course outlines and the Presentation Slides which will be used during the Course it will be available for all participants on CD .

BTS attendance certificate will be issued to all attendees completing minimum of 80% of the total course duration.

| Code | Date | Venue | Fees | Register |

|---|---|---|---|---|

| ME160-01 | 08-02-2026 | Dubai | USD 5450 | |

| ME160-02 | 04-05-2026 | Kuala-Lumpur | USD 5950 | |

| ME160-03 | 09-08-2026 | Casablanca | USD 5950 | |

| ME160-04 | 22-11-2026 | Dubai | USD 5450 |

Providing services with a high quality that are satisfying the requirements

Appling the specifications and legalizations to ensure the quality of service.

Best utilization of resources for continually improving the business activities.

BTS keen to selects highly technical instructors based on professional field experience

Since BTS was established, it considered a training partner for world class oil & gas institution

1st floor, Incubator Buildingو Masdar City, Abu Dhabi, UAE

Sun to Fri 09:00 AM to 06:00 PM

Contact Us anytime!

Request Info