Safe Operation and Maintenance of Circuit Breakers and Switchgear will equip participants with new or refreshed skills to ensure that circuit breakers and switchgear are installed, operated safely and maintained in a fashion that ensures safe and stable operation. Also they will be able to identified faults and ensure the underlying causes are identified to reduce possible further failures.

By the end of this course delegates will be able to:

Electrical Engineers, Electrical Supervisors and Senior Electrical Technicians engaged in the operation, maintenance and troubleshooting, of circuit breakers, interruptive devices and switchgear control centers.

This interactive Training will be highly interactive, with opportunities to advance your opinions and ideas and will include;

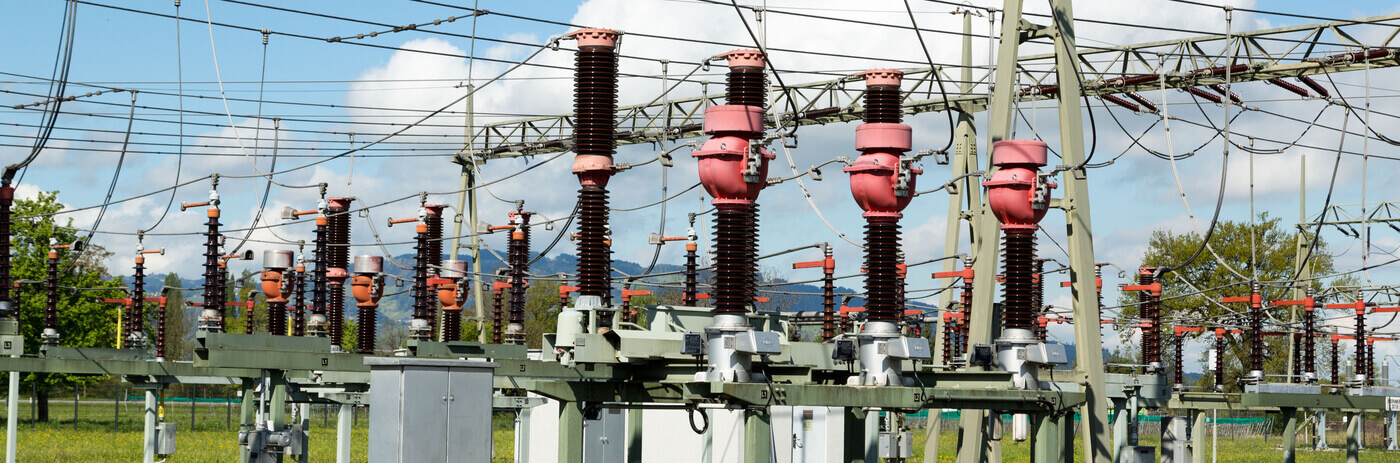

The Technology of Circuit Breakers and Switchgear

Operation of Various Types of Interrupting Equipment

The Operation & Maintenance of Circuit Breakers & Switchgear

The Use of Test Equipment

Special Techniques

The Interpretation and Use of Drawings

The Development of a Job Plan

The Identification and Repair of Problems Failures

BTS attendance certificate will be issued to all attendees completing a minimum of 80% of the total course duration.

| Code | Date | Venue | Fees | Register |

|---|---|---|---|---|

| EE128-01 | 26-04-2026 | Cairo | USD 5450 | |

| EE128-02 | 06-07-2026 | Istanbul | USD 5950 | |

| EE128-03 | 20-09-2026 | Dubai | USD 5450 | |

| EE128-04 | 22-11-2026 | Marrakesh | USD 5950 |

The duty of a circuit breaker is to switch on and switch off, once or repeatedly several times different electrical circuits during normal as well as abnormal operating conditions. Circuit breakers an ...

Preventing the unintentional ignition of explosive atmospheres is a critical safety and economic aspect of all petroleum and chemical plant operations.

Your transformer is a valuable device with many mechanical and chemical processes taking place all the time. This course combines theoretical and practical aspects of transformer design, operation, ma ...

Providing services with a high quality that are satisfying the requirements

Appling the specifications and legalizations to ensure the quality of service.

Best utilization of resources for continually improving the business activities.

BTS keen to selects highly technical instructors based on professional field experience

Since BTS was established, it considered a training partner for world class oil & gas institution

1st floor, Incubator Buildingو Masdar City, Abu Dhabi, UAE

Sun to Fri 09:00 AM to 06:00 PM

Contact Us anytime!

Request Info