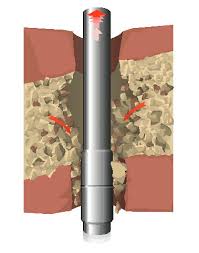

The course covers to moderate practices angle well bores, extended reach and horizontal drilling. Loads simple drill stem design for vertical applied by tension, combined torsion, burst pressure, collapse pressure, compression, slip and stability forces are considered. Design steps to reduce fatigue damage are also covered.

By the end of this course delegates will be able to:

Drilling Engineers, Senior Drilling Engineers, Drilling Supervisors, Work over Engineers, Petroleum Engineers, Completion Engineers, Tool Pushers, Reservoir and Senior Reservoir Engineers, Geologists, Production Engineers & Technologists, Well site Engineers, Lifting Personnel, Maintenance Engineers, Foremen, Industry Personnel.

This interactive Training will be highly interactive, with opportunities to advance your opinions and ideas and will include;

BTS attendance certificate will be issued to all attendees completing minimum of 80% of the total course duration.

| Code | Date | Venue | Fees | Register |

|---|---|---|---|---|

| DE122-01 | 04-05-2026 | Kuala-Lumpur | USD 5950 | |

| DE122-02 | 21-06-2026 | Manama | USD 5450 | |

| DE122-03 | 06-09-2026 | Marrakesh | USD 5950 | |

| DE122-04 | 07-12-2026 | Istanbul | USD 5950 |

This course is designed to address how to optimize drilling performance from all aspects of the drilling process. The course will address bit performance diagnostics, technical limits, and the way tha ...

Downhole Remediation for Mature Oil and Gas Wells is presented from a practical point of view. Discussions include decision processes for selection, design, and application of methods that are support ...

This course will be all about prevention rather than cure. It will teach the complete process of detection, diagnostics, and resolution in a methodical way. The candidates will be working in teams to ...

Providing services with a high quality that are satisfying the requirements

Appling the specifications and legalizations to ensure the quality of service.

Best utilization of resources for continually improving the business activities.

BTS keen to selects highly technical instructors based on professional field experience

Since BTS was established, it considered a training partner for world class oil & gas institution

1st floor, Incubator Buildingو Masdar City, Abu Dhabi, UAE

Sun to Fri 09:00 AM to 06:00 PM

Contact Us anytime!

Request Info