This corrosion course provides an excellent avenue for corrosion practitioners, researchers, designers, technical managers, inspection and maintenance engineers, quality control personnel and those involved in failure analysis to update their appreciation of corrosion prevention through materials selection and design.

By the end of this course delegates will be able to:

Corrosion Control Engineers & Personnel, Process Engineers, Metallurgists, Inspection Personnel, Mechanical Engineers, Material Selection Personnel, Plant Contractors, Operations Engineers, Team Leaders & Supervisors, Maintenance Supervisors, Senior Plant Supervisors, Mechanical Engineers, Corrosion Control & Monitoring Systems Personnel, Oil and Gas Production Facilities Personnel, Chemists, Chemical Engineers, Technicians and Supervisors, New Petroleum Engineers, Asset Management Personnel, Design & Construction Engineers, Team Leaders & Coordinators, Construction Coordinators, Maintenance Engineers, Technologists, Maintenance Team Leaders & Engineers, Personnel who are / will be responsible for detecting, inspecting, monitoring, controlling corrosion in oil and gas piping, pipelines used in production operations and Personnel responsible for metallurgy, corrosion or the prevention of failures in plant and equipment.

Basic Concepts in Corrosion

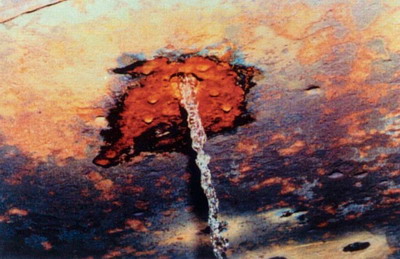

Different Forms of Corrosion: Mechanisms, Recognition & Prevention

Materials Selection Overview

Corrosion Resistance of Common Metals and Alloys

Design against Corrosion

BTS attendance certificate will be issued to all attendees completing minimum of 75% of the total course duration.

| Code | Date | Venue | Fees | Register |

|---|---|---|---|---|

| PE122-01 | 03-05-2026 | Manama | USD 5450 | |

| PE122-02 | 19-07-2026 | Casablanca | USD 5950 | |

| PE122-03 | 18-10-2026 | Dubai | USD 5450 | |

| PE122-04 | 20-12-2026 | Cairo | USD 5450 |

This basic corrosion course covers fundamental aspects of corrosion control and its prevention. The course will enable beginners to establish a solid foundation in corrosion before moving on to advanc ...

Corrosion problems have always presented a severe challenge to oil and gas producing operations. Operators plan for long periods of continuous production with maintenance schedules for the prescribed ...

This course provides a comprehensive overview of white cement manufacturing, covering raw materials, production processes, quality control, and applications. It is designed to enhance technical knowle ...

Proper selection of materials and design are most effective in cutting the cost of corrosion and achieving low cost reliability as corrosion can be designed out of the system. It is always easier and ...

Providing services with a high quality that are satisfying the requirements

Appling the specifications and legalizations to ensure the quality of service.

Best utilization of resources for continually improving the business activities.

BTS keen to selects highly technical instructors based on professional field experience

Since BTS was established, it considered a training partner for world class oil & gas institution

1st floor, Incubator Buildingو Masdar City, Abu Dhabi, UAE

Sun to Fri 09:00 AM to 06:00 PM

Contact Us anytime!

Request Info