The course provides training in the understanding and interpretation of HSE Regulations related to drilling and wells. The course focuses on a number of key elements including the design of drilling facilities, well construction, drilling operations and maintenance. The course explains how drilling and completion operations are planned and executed to meet all HSE objectives, maximize well productivity, and cater for future work over and intervention needs. HSE concepts and methods are presented together with down-hole equipment, tools and their selection criteria.

By the end of this BTS training course, participants will be able to:

Drilling Engineers, Senior Drilling Engineers, Drilling Supervisors, Drilling Superintendents, Petroleum Engineers, Completion Engineers, Tool Pushers, Reservoir and Senior Reservoir Engineers, Geologists, Production and Completion Engineers, Foremen, Work over Engineers, Petroleum Engineers, Completion Engineers, Tool Pushers, Reservoir and Senior Industry Personnel, Lifting Personnel, Maintenance Engineers, Technologists, Mud Engineers, Well Site Supervisors, Drilling Contractors, Drilling Supervisors, Completion Engineers, Completion Supervisors, Drilling Managers, Drilling Technical Support Personnel, Trainee Drillers, Rig Engineers, Industry Personnel, Completion engineers, Production staff, Petroleum engineers,

Other technical staff that need an understanding and an appreciation of HSE aspects of well drilling, completion, work-over and well intervention, Roustabouts, Roughnecks, Derrick men, Assistant Drillers and leading drilling personnel offshore, Employees and managers in drilling service Companies, Management of drilling rigs and drilling installations, Engineering personnel for design and modification of drilling facilities, Safety Delegates, Safety Coaches Professionals

This interactive Training will be highly interactive, with opportunities to advance your opinions and ideas and will include;

Packer and Tubing Movement, Completion Materials

Casing and Tubing Hangers

Well Control Techniques

Safe Practices (Onshore and Offshore)

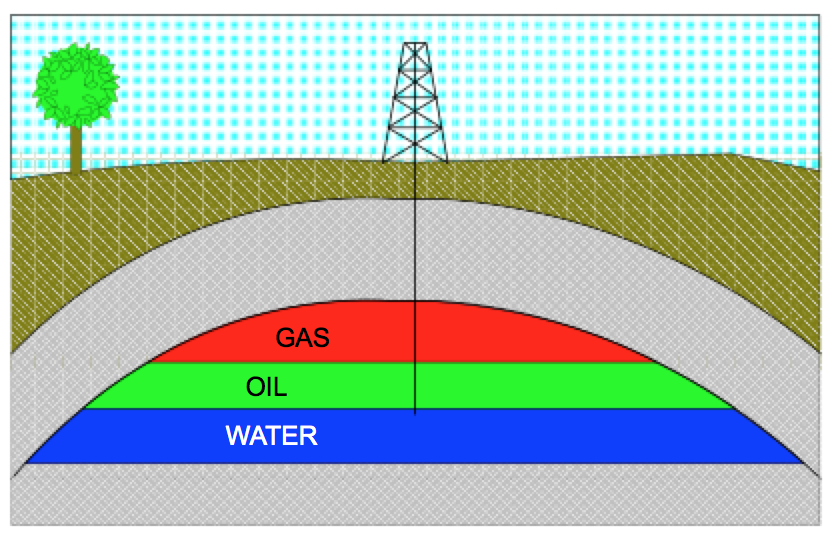

Introduction to Reservoir Properties

Planning Essentials Prior to Drilling

Wellbore Tubing-Casing Configuration, Completion Procedures

Completion Variations

Conductors, Casing and Tubing: Different Reservoir Types

Estimation of Pressure Losses in Tubing for Different Rock and Fluid Properties, Tubing Torque and Pressure Testing and Tubing Dimensions

BTS attendance certificate will be issued to all attendees completing minimum of 80% of the total course duration.

| Code | Date | Venue | Fees | Register |

|---|---|---|---|---|

| DE106-01 | 08-02-2026 | Dammam | USD 5450 | |

| DE106-02 | 21-06-2026 | Manama | USD 5450 | |

| DE106-03 | 21-09-2026 | Istanbul | USD 5950 | |

| DE106-04 | 06-12-2026 | Cairo | USD 5450 |

The Advanced Completions and Workovers course is an introduction to many facets of completion and intervention technology. The material progresses through each of the major design, diagnostic and inte ...

Well servicing and work over is concerned with maintaining production from wells. Cleanout and work over involves the reconditioning of wells that are no longer producing properly. This introductory t ...

This course teaches the physical principles and concepts related to maintaining and regaining control of formation pressures while drilling a well. It is suitable for persons desiring to learn the com ...

Hydrocarbon systems found in petroleum reservoirs are known to display multi-phase behavior over wide ranges of pressure and temperatures. The most important phases that occur in petroleum reservoirs ...

With competent health and safety personnel who drives this force, the Oil and Gas Exploration Industries will continue to be a safe place to workers. The conventional oil and gas well industry calls f ...

Providing services with a high quality that are satisfying the requirements

Appling the specifications and legalizations to ensure the quality of service.

Best utilization of resources for continually improving the business activities.

BTS keen to selects highly technical instructors based on professional field experience

Since BTS was established, it considered a training partner for world class oil & gas institution

1st floor, Incubator Buildingو Masdar City, Abu Dhabi, UAE

Sun to Fri 09:00 AM to 06:00 PM

Contact Us anytime!

Request Info