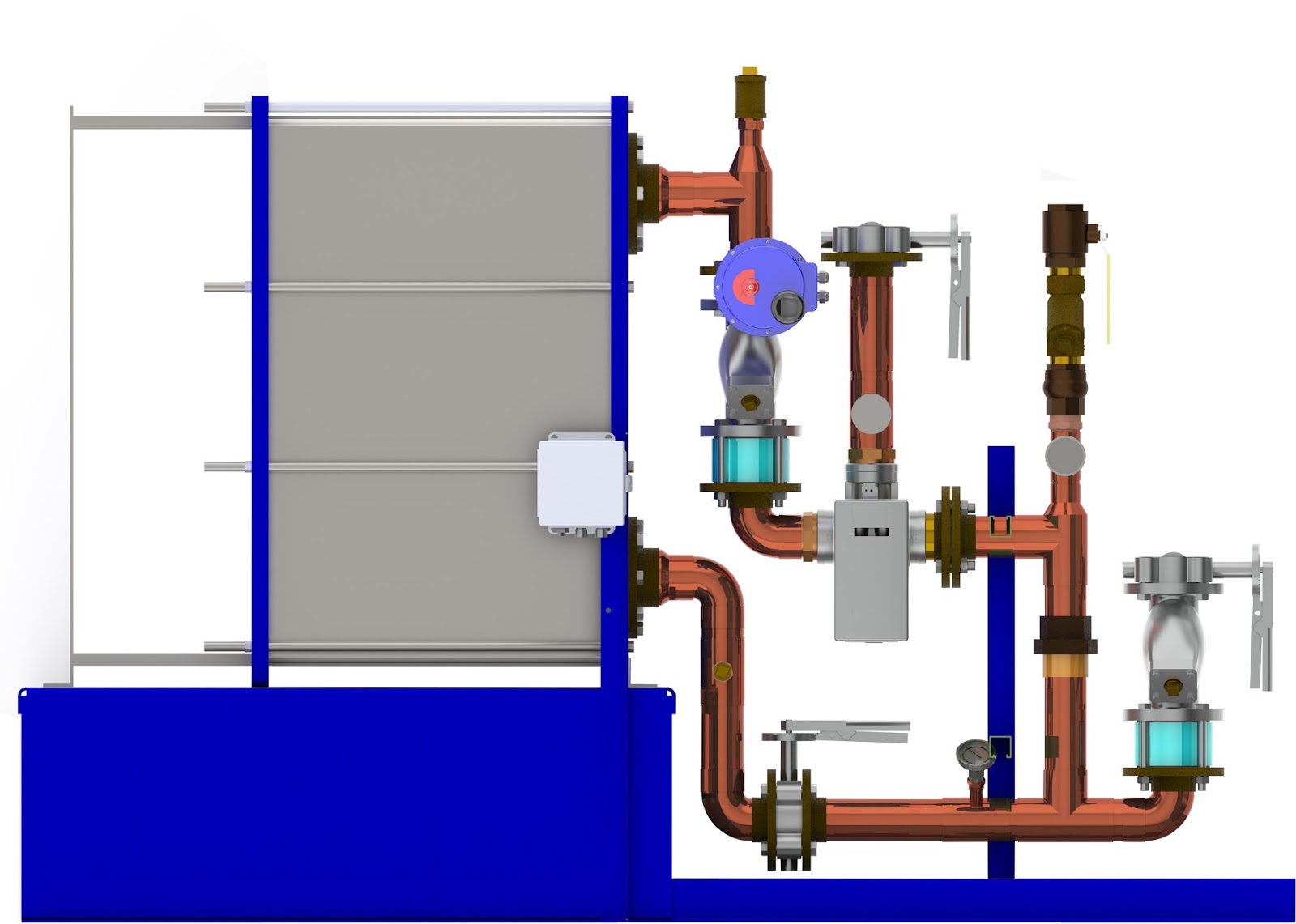

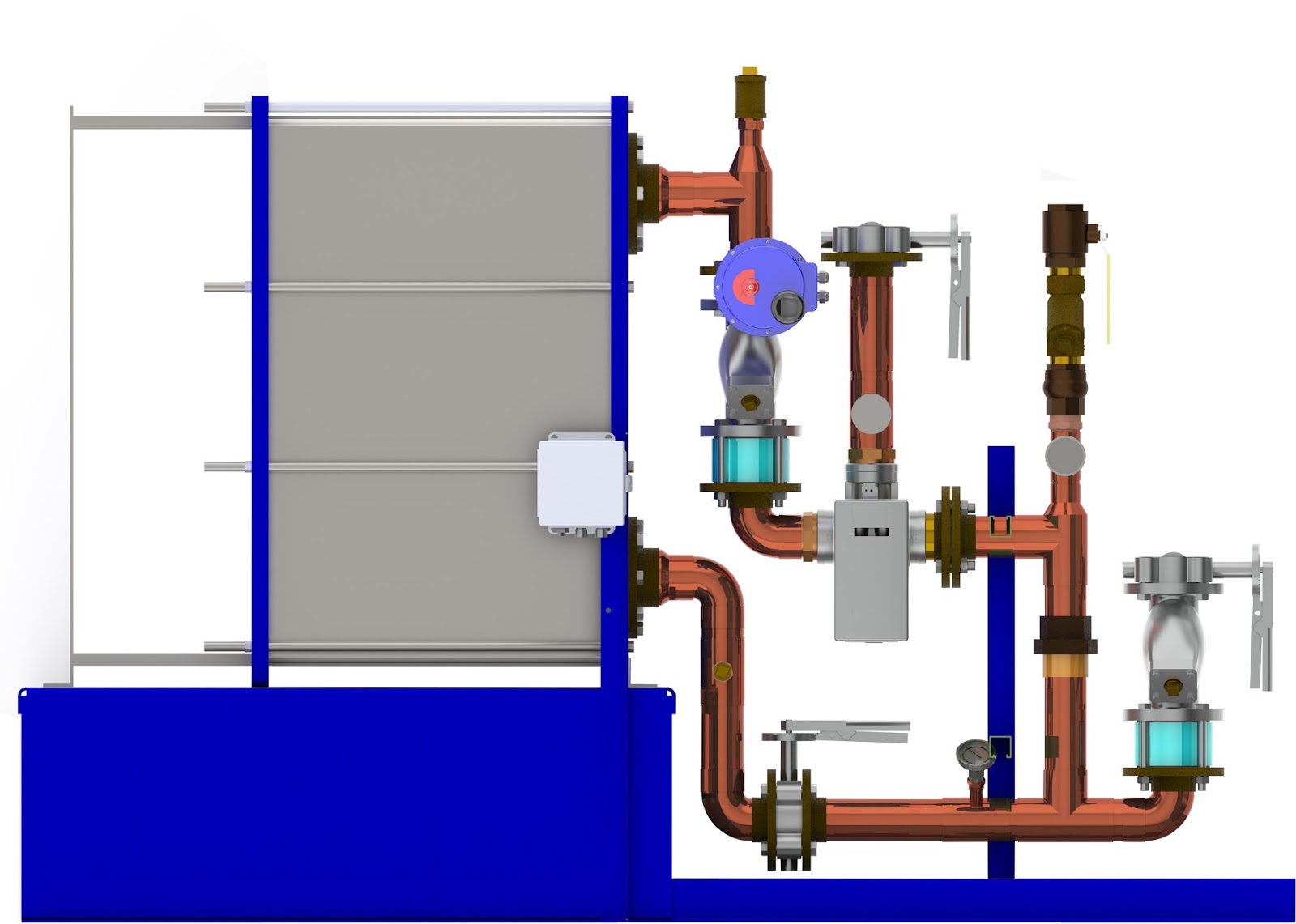

- Description of Thermal Equipment

- Heat Transfer

- Heat Exchangers

- Heat exchange law in relation to the mode of fluids circulation

- Furnaces and Boilers

To provide practical and applied knowledge relating to the conditions of heat transfer and the workings of thermal equipment in the chemical and petroleum industries.

Description of Thermal Equipment

Heat Transfer

Heat Exchangers

Heat exchange law in relation to the mode of fluids circulation: single counter-current

Furnaces and Boilers

heat exchanges in the radiation zone

BTS attendance certificate will be issued to all attendees completing minimum of 80% of the total course duration.

| Code | Date | Venue | Fees | Register |

|---|---|---|---|---|

| ME179-01 | 10-05-2026 | Amman | USD 5450 | |

| ME179-02 | 02-08-2026 | Manama | USD 5450 | |

| ME179-03 | 19-10-2026 | Istanbul | USD 5950 | |

| ME179-04 | 13-12-2026 | Dubai | USD 5450 |

Providing services with a high quality that are satisfying the requirements

Appling the specifications and legalizations to ensure the quality of service.

Best utilization of resources for continually improving the business activities.

BTS keen to selects highly technical instructors based on professional field experience

Since BTS was established, it considered a training partner for world class oil & gas institution

1st floor, Incubator Buildingو Masdar City, Abu Dhabi, UAE

Sun to Fri 09:00 AM to 06:00 PM

Contact Us anytime!

Request Info