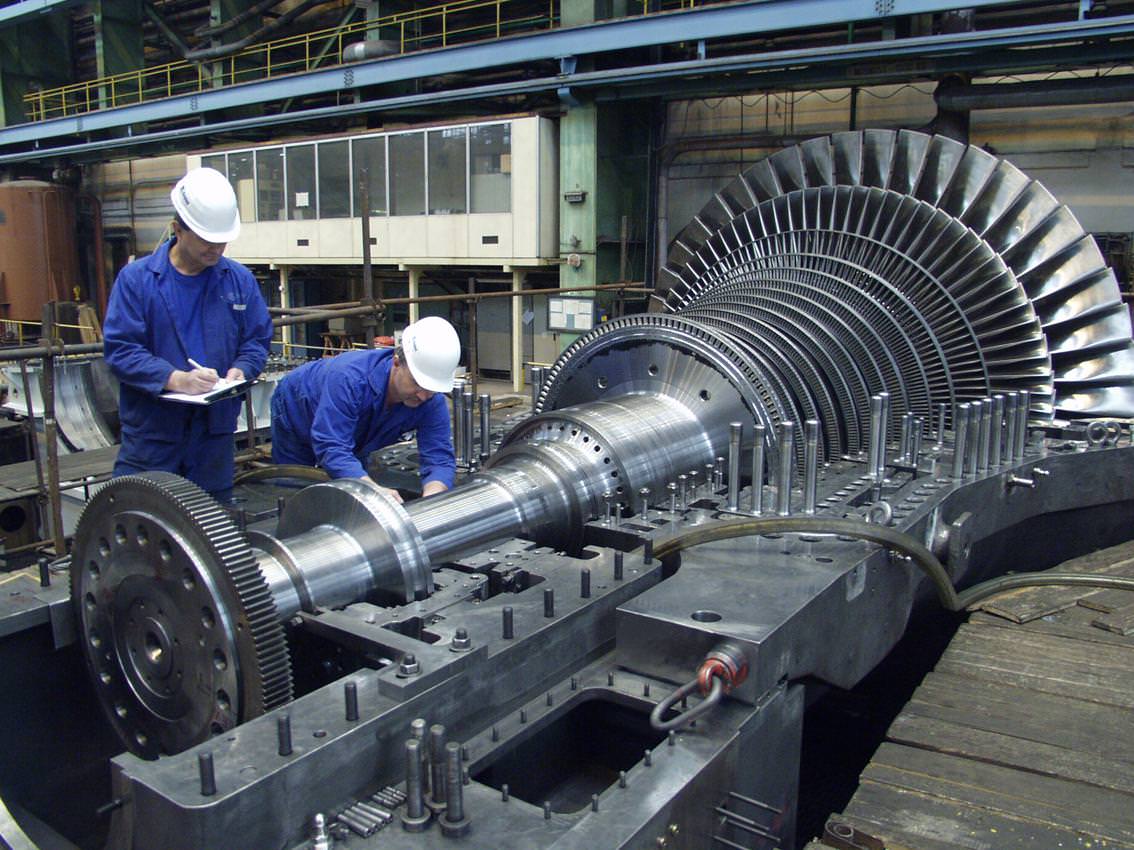

The course is particularly directed at inspection and maintenance engineers who are concerned with corrosion of the structures of petroleum production. This course covers both the fundamentals and practices in designing, operating and maintaining corrosion and corrosion control for petroleum metallic structures.

By the end of this course delegates will learn about:

Corrosion Control Engineers & Personnel, Process Engineers, Metallurgists, Inspection Personnel, Mechanical Engineers, Material Selection Personnel, Plant Contractors, Operations Engineers, Team Leaders & Supervisors, Maintenance Supervisors, Senior Plant Supervisors, Mechanical Engineers, Corrosion Control & Monitoring Systems Personnel, Oil and Gas Production Facilities Personnel, Chemists, Chemical Engineers, Technicians and Supervisors, Personnel who are / will be responsible for detecting, inspecting, monitoring, controlling corrosion in oil and gas piping, pipelines used in production operations and Personnel responsible for metallurgy, corrosion or the prevention of failures in plant and equipment

This interactive Training will be highly interactive, with opportunities to advance your opinions and ideas and will include;

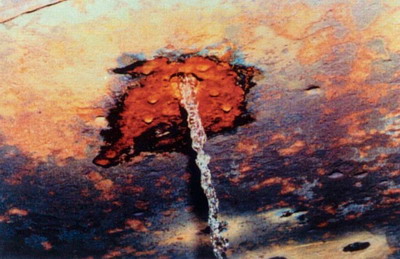

Fundamentals of Corrosion

Testing & Monitoring Techniques

Cathodic Protection

Sacrificial Anode Cathodic Protection

Impressed Current Cathodic Protection

Criteria for Cathodic Protection: Instrumentation for Cathodic Protection of Underground Pipelines

Cathodic Protection of Underground Pipelines

Stray Current Corrosion and Methods of Prevention

Pipeline Coatings and the Effectiveness of Coatings

Cathodic Protection and Coatings: Pipeline Inspection: Survey Methods and Evaluation Techniques

Corrosion Principles

Attachments

Fundamentals of Corrosion Mechanisms

Corrosion Monitoring Techniques

Basics of Corrosion Prevention

Fundamentals of Cathodic Protection

CP Principles: CP for Special Applications

CP Attachments

BTS attendance certificate will be issued to all attendees completing minimum of 80% of the total course duration

| Code | Date | Venue | Fees | Register |

|---|---|---|---|---|

| FAC119-02 | 11-05-2026 | Istanbul | USD 5950 | |

| FAC119-03 | 10-08-2026 | Kuala-Lumpur | USD 5950 | |

| FAC119-04 | 13-12-2026 | Dubai | USD 5450 |

The removal of acidic components (primarily H2S and CO2) from hydrocarbon streams can be broadly categorized as those depending on chemical reaction, or adsorption. Processes employing each of these t ...

This basic corrosion course covers fundamental aspects of corrosion control and its prevention. The course will enable beginners to establish a solid foundation in corrosion before moving on to advanc ...

Corrosion problems have always presented a severe challenge to oil and gas producing operations. Operators plan for long periods of continuous production with maintenance schedules for the prescribed ...

Corrosion problems have always presented a severe challenge to oil and gas producing operations. Operators plan for long periods of continuous production with maintenance schedules for the prescribed ...

Providing services with a high quality that are satisfying the requirements

Appling the specifications and legalizations to ensure the quality of service.

Best utilization of resources for continually improving the business activities.

BTS keen to selects highly technical instructors based on professional field experience

Since BTS was established, it considered a training partner for world class oil & gas institution

1st floor, Incubator Buildingو Masdar City, Abu Dhabi, UAE

Sun to Fri 09:00 AM to 06:00 PM

Contact Us anytime!

Request Info