This course explores the construction and configuration of the screw gas compressor in some detail:

Reliability Engineers, Maintenance Managers, Engineers & Planners, Reliability and Maintenance Engineers, Facilities and Utilities Managers, Design Engineers, Top Level Maintenance Technicians, OE Champions, Predictive and Preventive Maintenance, Technicians & Supervisors, Planners, Maintenance Supervisors, Crafts and Tradesmen, Operations Supervisors, Process Engineers, Inspectors and Inspection Supervisors, Equipment Engineers Team Leaders and Professionals in Maintenance, Engineering and Production, Maintenance managers, reliability and maintenance Engineers, Production Managers, Plant Engineers, Design Engineers, Reliability Engineers and Technicians, Operators, Safety Engineers, Risk Engineers, Safety Engineers and anyone who is involved in Reliability Engineering strategies or methodologies to include design engineers for capital projects engineers, Foreman and Technicians, Mechanical, Electrical and Operational Personnel, Personnel designated as Planners, Key leaders from each maintenance craft, Key operations personnel, Technical professionals responsible for maintenance and repair of equipment, Professionals involved in inspection and maintenance and repair, professionals involved in asset & maintenance management auditing, Quality & Compliance Managers, Lead Auditors & Audit Team Members, Process Controllers, Maintenance Supervisors, Maintenance Planners, Predictive Maintenance Technicians & Supervisors, Materials Management Managers and Supervisors, Service Company Representatives, Asset owners & Asset Managers

Mechanical Aspects of Screw Gas Compressors

These sessions will be covering the following Key Topics:

Control & Operation of Screw Gas Compressors

Key topics to be covered may include

Case studies will be used and participants will be encouraged to solve problems for themselves.

Natural Gas Compression Using Screw Compressors

The design and operation of oil-injected screw compressor units used in typical natural gas field booster compression and propane refrigeration applications. The sessions are designed for the selection, operation, and troubleshooting of screw compressors.

Topics to be covered

Compressor Operation In A Process System

Basic Compression Theory

Operation & Design of Screw Compressors

Key Topics Covered:

Frame Assemblies and Compressor Configurations

Cooling and Lubrication

Performance & design calculations

Case Studies and Compressor Applications

Control of Screw Compressors

These sessions gives a thorough introduction to the Control, Design and Operation of screw compressors. This type of compressor is used for both air and process gas applications

Key Topics Covered:

Screw Compressors Operation And Maintenance

These sessions define functions, operation and condition monitoring of major types of screw compressors. It considers and discusses performance and maintenance requirements of compressor units installed on your sites.

Key Issues To be covered:

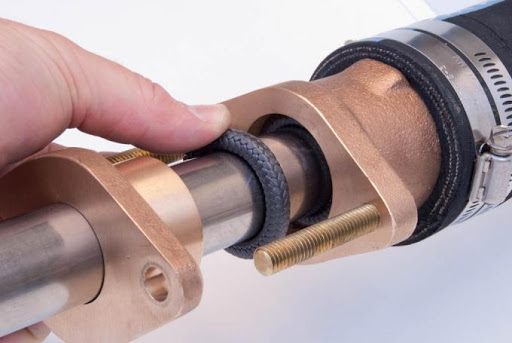

Dry Gas Seals

The Evolution of Dry Gas Seals

Introduction to Dry Gas Seals

Dry Gas Seal Configurations

BTS attendance certificate will be issued to all attendees completing minimum of 80% of the total course duration.

| Code | Date | Venue | Fees | Register |

|---|---|---|---|---|

| MI234-01 | 27-04-2026 | Istanbul | USD 5950 | |

| MI234-02 | 19-07-2026 | Dubai | USD 5450 | |

| MI234-03 | 27-09-2026 | Marrakesh | USD 5950 | |

| MI234-04 | 06-12-2026 | Cairo | USD 5450 |

This course defines functions, operation and condition monitoring of Major types of reciprocating screw. It considers and discusses Performance and maintenance requirements of compressor units Install ...

In this 5-day course, participants will gain a strong technical and practical understanding of mechanical seals and gland packing through the exploration of design features and implications of many se ...

Providing services with a high quality that are satisfying the requirements

Appling the specifications and legalizations to ensure the quality of service.

Best utilization of resources for continually improving the business activities.

BTS keen to selects highly technical instructors based on professional field experience

Since BTS was established, it considered a training partner for world class oil & gas institution

1st floor, Incubator Buildingو Masdar City, Abu Dhabi, UAE

Sun to Fri 09:00 AM to 06:00 PM

Contact Us anytime!

Request Info