This seminar will provide the following information for all types of generators, exciters, automatic voltage regulators (AVR’s), and protective systems:

Each delegate will receive a copy of the following materials written by the instructor:

This interactive Training will be highly interactive, with opportunities to advance your opinions and ideas and will include;

Module 1 – Fundamentals of Electrical Systems, Synchronous Machines, Synchronou Generators

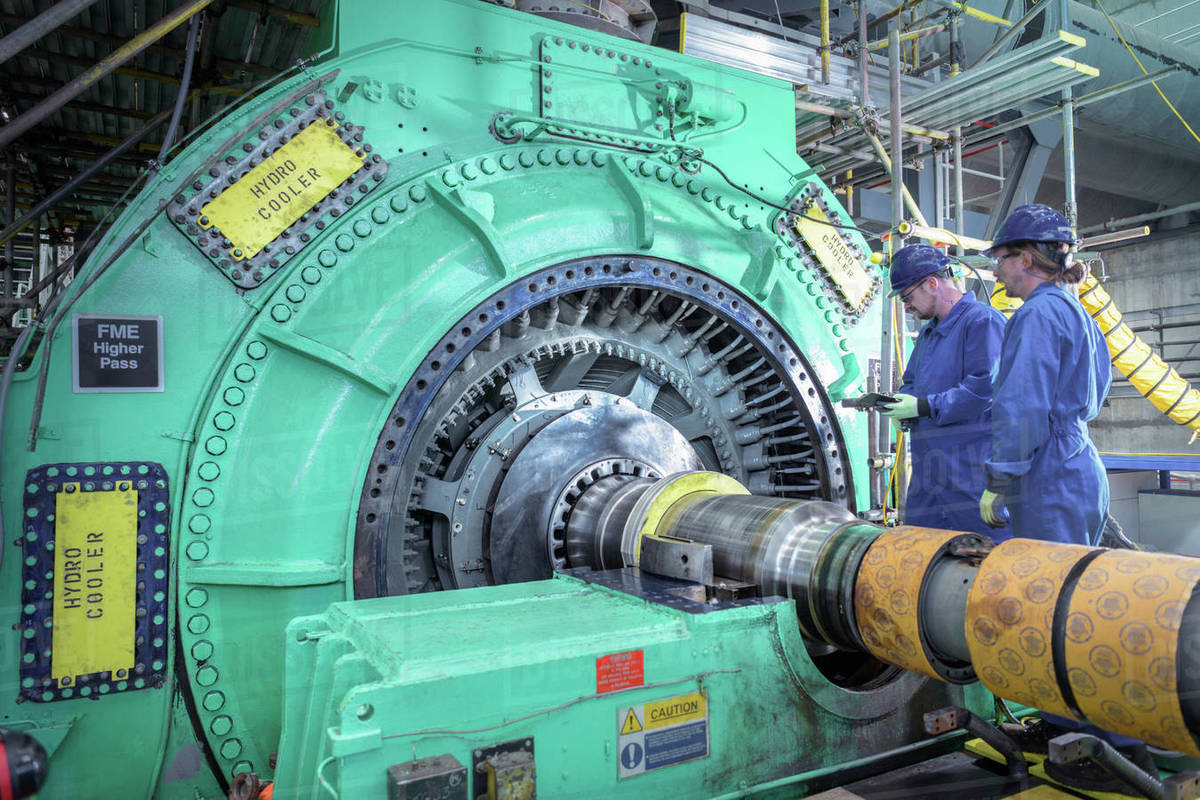

Module 2 – Generator Components, Auxiliaries and Excitation, Generator Main Generators

Module 3 – Generator Surveillance and Testing, Generator Inspection and Maintenance, Generator Rotor Reliability and Life Expectancy, Bearings and Lubrication,Used Oil Analysis, Vibration Analysis, Power Station Electrical Systems andDesign Requirements, Power Station Protective Systems, Frequently Asked Questions

BTS attendance certificate will be issued to all attendees completing a minimum of 80% of the total course duration.

| Code | Date | Venue | Fees | Register |

|---|---|---|---|---|

| EE165-01 | 26-04-2026 | Dubai | USD 5450 | |

| EE165-02 | 05-07-2026 | Manama | USD 5450 | |

| EE165-03 | 13-09-2026 | Amman | USD 5450 | |

| EE165-04 | 15-11-2026 | Dubai | USD 5450 |

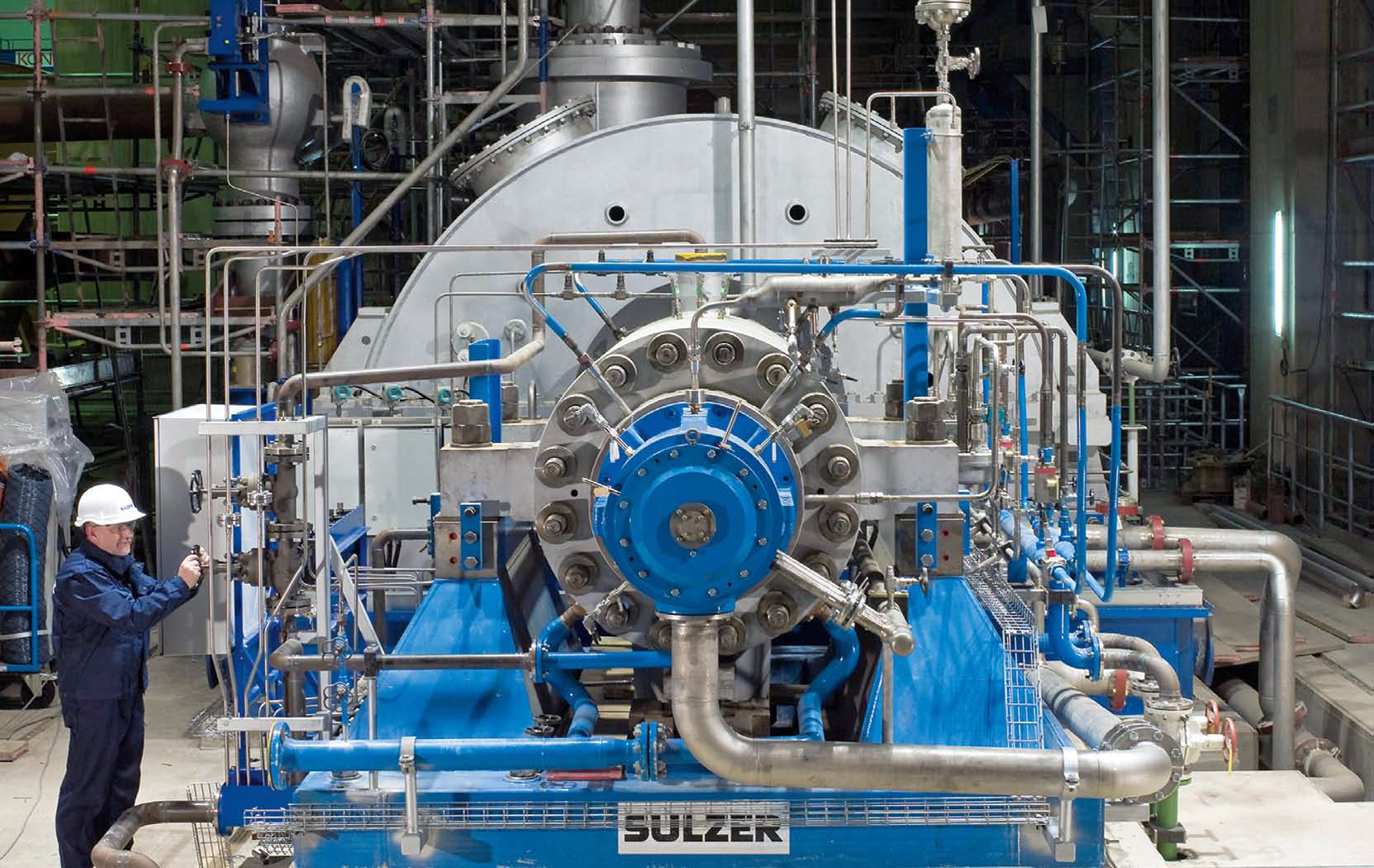

This comprehensive course is regarded as an essential course for those engineers and electricians involved with the operations and maintenance of Gas or Steam Turbine driven Generator systems. This co ...

This 5 days seminar is designed to provide excellent understanding on both a theoretical and practical level for power generators. The workshop starts at a basic level, to ease the engineer and techni ...

Providing services with a high quality that are satisfying the requirements

Appling the specifications and legalizations to ensure the quality of service.

Best utilization of resources for continually improving the business activities.

BTS keen to selects highly technical instructors based on professional field experience

Since BTS was established, it considered a training partner for world class oil & gas institution

1st floor, Incubator Buildingو Masdar City, Abu Dhabi, UAE

Sun to Fri 09:00 AM to 06:00 PM

Contact Us anytime!

Request Info