The program is tailored to equip participants with skills to develop, evaluate, and improve electrical and instrumentation systems for a wide range of industries.

By the end of this course, participants will be able to:

This course is ideal for:

This BTS training course will combine presentations with interactive practical exercises, supported by video materials, activities and case studies. Delegates will be encouraged to participate actively in relating their particular protection requirements at their workplace.

There will be adequate time given for group discussion during and at the end of each session, including detailed case studies and anecdotes on based on the subject matter and the facilitator’s own experience in the field.

Day 1: Introduction to Electrical and Instrumentation Design

Day 2: Electrical Design Basics

Day 3: Instrumentation Design Essentials

Day 4: Integration of Electrical and Instrumentation Systems

Day 5: Practical Applications, Standards, and Best Practices

BTS attendance certificate will be issued to all attendees completing a minimum of 80% of the total course duration.

| Code | Date | Venue | Fees | Register |

|---|---|---|---|---|

| EE158-01 | 12-04-2026 | Dubai | USD 5450 | |

| EE158-02 | 29-06-2026 | Istanbul | USD 5950 | |

| EE158-03 | 13-09-2026 | Dubai | USD 5450 | |

| EE158-04 | 13-12-2026 | Cairo | USD 5450 |

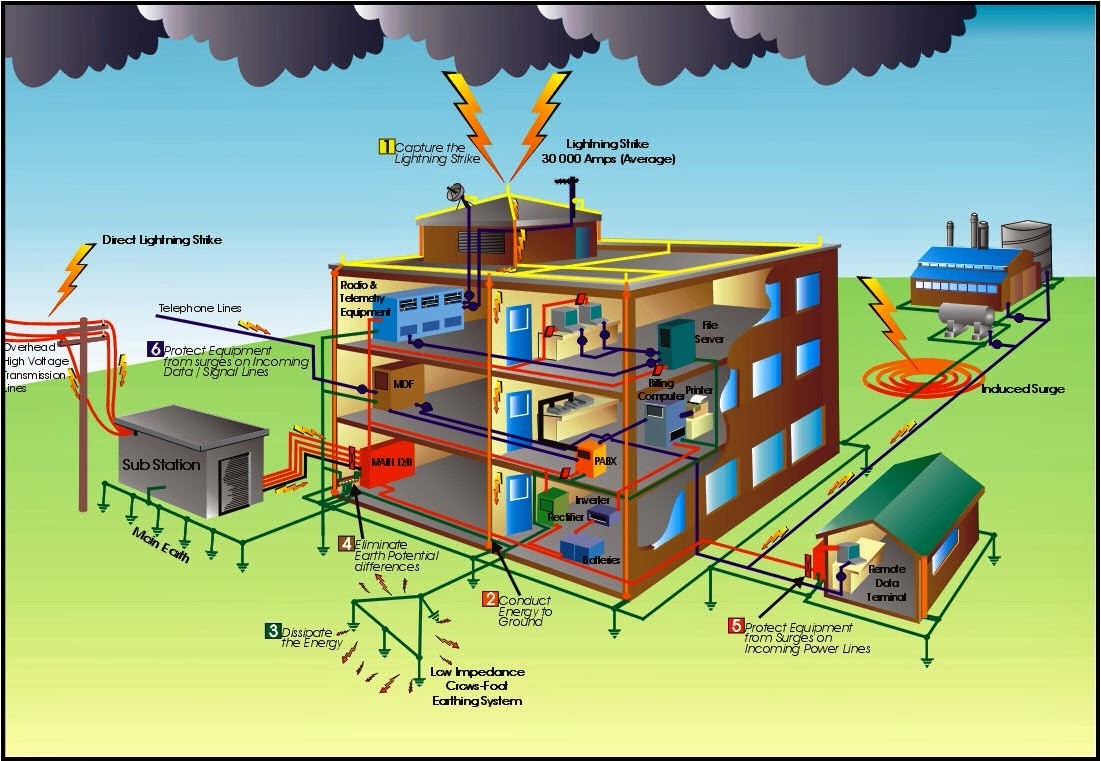

Earthing is an integral part of any electrical system. Properly selected earthing equipment will accomplish many desirable objectives, such as: • Improving the system operating characteristics. • Pr ...

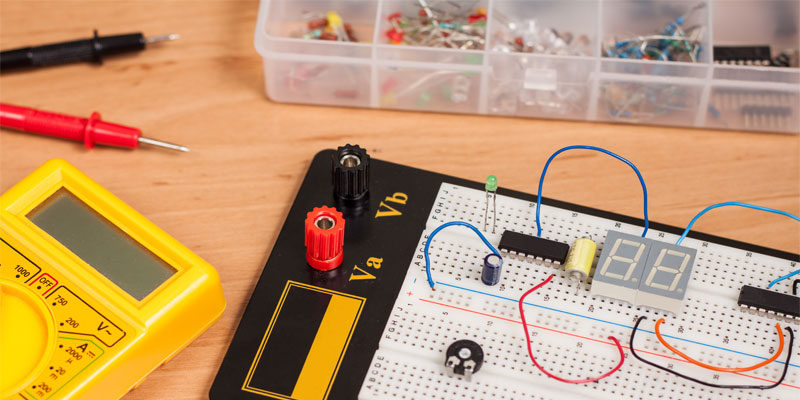

The safe and efficient operation of modern electrical equipment and control systems requires the successful testing, start-up and commissioning of this equipment or system to ensure the correct operat ...

Reliable service is dependent upon properly designed and periodically tested protective relay systems. These systems, and their protective relays, are explained for transmission lines, substations, an ...

Providing services with a high quality that are satisfying the requirements

Appling the specifications and legalizations to ensure the quality of service.

Best utilization of resources for continually improving the business activities.

BTS keen to selects highly technical instructors based on professional field experience

Since BTS was established, it considered a training partner for world class oil & gas institution

1st floor, Incubator Buildingو Masdar City, Abu Dhabi, UAE

Sun to Fri 09:00 AM to 06:00 PM

Contact Us anytime!

Request Info