This training course will feature:

By the end of this training course, participants will be able to:

This BTS training course is suitable to a wide range of professionals but will greatly benefit:

How will this Training Course be Presented?

This FLNG Operation and Maintenance training course will utilise a variety of proven adult learning techniques to ensure maximum understanding, comprehension and retention of the information presented. The daily workshops will be highly interactive and participative. This involves regular discussion between both delegates and course director. The training course will provide the participant with an in-depth knowledge through detailed information, real-life case studies, photos and video animation.

Day One: Introduction to LNG FPSO

Competency Description: The objective is to understand the key considerations of the design, operation and maintenance requirements of an FLNG.

Key behaviours

Topics to be covered

Day Two: The LNG Process Plant

Competency Description: The objective is to understand the operation, inspection and maintenance requirements and procedures of the systems and equipment to process well stream into LNG/LPG/Condensate.

Key behaviours

Topics to be covered

Day Three: Storage and Offloading

Competency Description: To develop an understanding of operation, inspection and maintenance requirements, challenges and safety risks of the containment and offloading system on a floating LNG facility.

Key behaviours

Topics to be covered

Day Four: Power Heating and Utility Systems

Competency Description: Malfunction of the utility and supporting systems may reduce, stop, or even endanger the production and personnel. The objective is to understand the operation and maintenance of the power generation system and the main process plant equipment and utilities.

Key behaviours

Topics to be covered

Day Five: Safety in Operation and Maintenance

Competency Description: Ensuring safety, operability and system / structural integrity are the main concerns on a FLNG. The objective is to gain a better knowledge of: how to optimize production and plant capacity while increasing safety levels and ensure environmental compliance.

Key behaviours

Topics to be covered

BTS attendance certificate will be issued to all attendees completing minimum of 75% of the total course duration.

| Code | Date | Venue | Fees | Register |

|---|---|---|---|---|

| PE152-01 | 12-04-2026 | Cairo | USD 5450 | |

| PE152-02 | 07-06-2026 | Jeddah | USD 5450 | |

| PE152-03 | 16-08-2026 | Cairo | USD 5450 | |

| PE152-04 | 22-11-2026 | Dubai | USD 5450 |

The main elements of the subsurface production system include the reservoir, wellbore, tubing, perforation techniques, packer, SSSV, artificial lift equipment and wellhead. Understanding the integrati ...

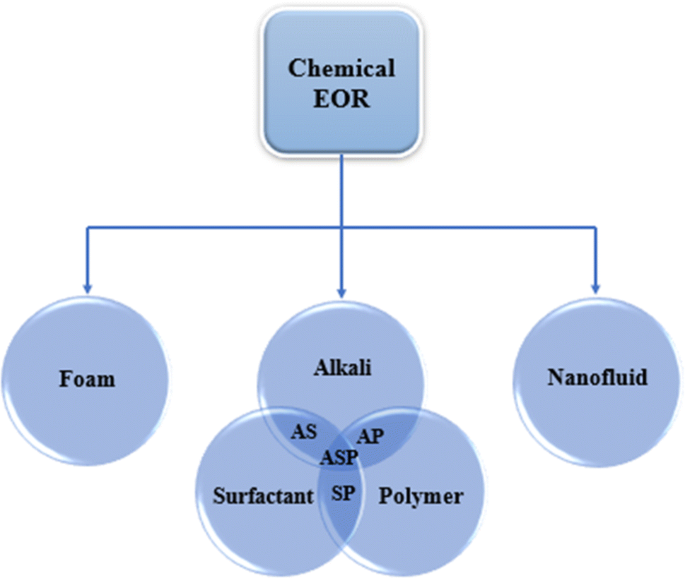

This course will provide comprehensive coverage of all chemical EOR processes. The course materials are based on the instructor’s hands-on experience, personal collection of field cases and learning, ...

Introduction Base oil (mineral and synthetic) is approximately 95 percent of the current lubricant market share. The lubricants business is a uniquely high value segment of the downstream. Almost e ...

As the complexities of real life systems increase so has to increase our understanding of them. Issues that are regularly arising in oil and gas exploration, production and transportation industries m ...

Providing services with a high quality that are satisfying the requirements

Appling the specifications and legalizations to ensure the quality of service.

Best utilization of resources for continually improving the business activities.

BTS keen to selects highly technical instructors based on professional field experience

Since BTS was established, it considered a training partner for world class oil & gas institution

1st floor, Incubator Buildingو Masdar City, Abu Dhabi, UAE

Sun to Fri 09:00 AM to 06:00 PM

Contact Us anytime!

Request Info