Course Details

Your Growth, Our Mission

Course Description

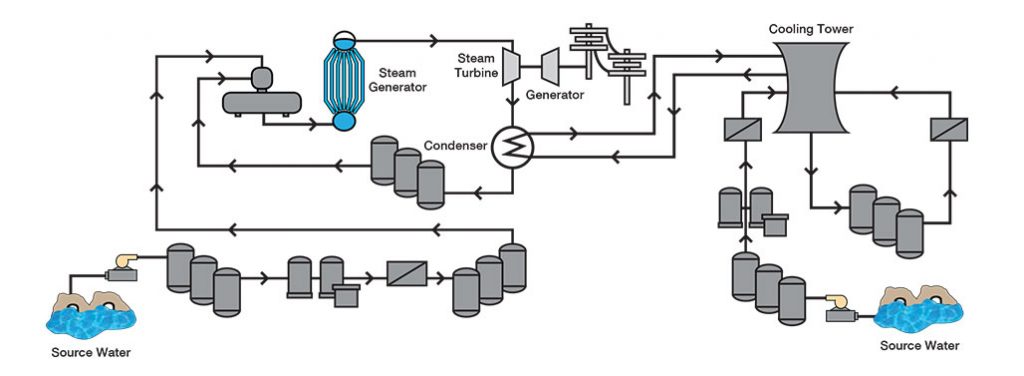

Boiler is an essential component of modern power plant as well as in any process and petrochemical plant. Modern boiler has to produce steam in an efficient and safe manner with the lowest operational cost that is practical. The safety of steam production and boiler operation presents important element in the overall steam production management. Boiler operation has to be in an environmentally acceptable way, including the aspects of combustion, but also chemical water treatment and other safety considerations.

This BTS training course will cover many important aspects of boiler operation, combustion control and feed water management. Methods of efficiency improvement of the boiler operation will be explained and discussed. Best practices for preventive and corrective maintenance based on inspection according to Codes & Standards will be explained and discussed. Problems in boiler operation will be discussed and problem-solving and troubleshooting will be illustrated through several real-world case studies and presented in the form of training courses. Maintenance and repair of the auxiliary mechanical equipment such as fans and pumps will be explained in detail.

The Training Course Will Highlight ?

Participants on the Boilers training course will develop the following competencies:

- Better understanding of boiler and steam generator technologies

- Parallel operation for generators

- Knowledge about effective operation and maintenance of boilers

- Complete understanding of water treatment and its impact on boiler performance

- Applying modern maintenance techniques for boilers (RBI, FMEA and RCA)

- Modern techniques for boiler control systems and close monitoring

Training Objective

Participants on the Boilers training course will develop the following competencies:

- Better understanding of boiler and steam generator technologies

- Parallel operation for generators

- Knowledge about effective operation and maintenance of boilers

- Complete understanding of water treatment and its impact on boiler performance

- Applying modern maintenance techniques for boilers (RBI, FMEA and RCA)

- Modern techniques for boiler control systems and close monitoring

Target Audience

- Technicians and Engineers in charge of Boiler Operation

- Technical Personnel dealing with Boilers Maintenance

- Boiler Inspectors and Contractors

- Technical Personnel in charge of Steam Generation and Distribution Systems

Training Methods

This interactive Training will be highly interactive, with opportunities to advance your opinions and ideas and will include;

- Lectures

- Workshop & Work Presentation

- Case Studies and Practical Exercise

- Videos and General Discussions

Daily Agenda

Day 1: Overview of Steam Generation and Use

- Overview of Boiler Types and Industrial Steam Generators

- Elements of Boiler Plant: Fired Tube Boilers and Water Tube Boiler

- Steam Generation Basics

- Generation operation parameters

- Power types - KW, KVAR, KVA

- Synchronization techniques and basic conditions

- Flame Characteristics

- Products of Combustion and Environmental Regulations

Day 2: Boiler Efficiency and Performance

- Boiler Efficiency: Economic and Environmental Aspects

- Boiler Feed Water Preheating Train

- Air Economizers and Waste Heat Utilization

- Boiler Performance and Specifications

- Evaluating Boiler Efficiencies

- Boiler Blow-Down Control Recovery

- Steam Distribution System Losses

Day 3: Boiler Safety Operation and Control

- Boiler Control Strategies: Safeguards, Interlocks and Alarm Systems

- Explain PLC for boiler controls (practical)

- Burner Management System (BMS)

- Safe Start Up and Shutdown Procedure

- Scale and Corrosion Control

- Chemical & Physical Treatment of Feed Water

- De-aeration of Feed Water: Removing of Oxygen and CO2

Day 4: Boiler Inspection, Maintenance and Repairs

- Routine & Periodic Boiler Inspections: Risk Based Inspection (RBI)

- Common Boiler Problems in Operation

- Abnormal Operating Conditions and Operator Actions

- Maintenance Work Done Periodically

- Checklist for Maintenance of Fuel Supply System

- Maintenance of Condensate Recovery and treatment

- Using CMMS (computer management maintenance systems)

Day 5: Boiler Troubleshooting and Accident Prevention

- Boiler Failures and Accidents: Root Cause Analysis

- How to apply FMEA (Failure Mode Effective Analysis)

- Boiler Troubleshooting Guide

- Applying RBI (Risk-Based Inspection techniques)

Accreditation

BTS attendance certificate will be issued to all attendees completing a minimum of 80% of the total course duration.

Quick Enquiry

Request Info

Related Courses

Your Growth, Our Mission