Course Details

Your Growth, Our Mission

Course Description

This is a 5 days course designed to provide the participants with an understanding of the various codes and symbols used to illustrate instrumentation in industrial facilities.

Instrument codes and symbols are graphically represented in technical diagrams such as Process Flow Schemes (PFD) and in Pipeline and Instrumentation Drawings (P&ID).

Such drawings are of particular importance to operation and maintenance technicians who are required to understand the process control systems associated with an installation.

However, difficulties are often experienced primarily due to the existence of several systems of instrument codes and symbols which have been developed over the years by owners and contractors who carry out the engineering design, construction and operation of processing installations.

The Training Course Will Highlight ?

Training Objective

Target Audience

This Intensive Five-day instructional program covering the educational needs of Instrumentation and Control Engineers, Operation Engineers, and Process / Utility Supervisors. No specific prerequisite training or experience required for registration.

Training Methods

This interactive Training will be highly interactive, with opportunities to advance your opinions and ideas and will include;

- Lectures

- Workshop & Work Presentation

- Case Studies and Practical Exercise

- Videos and General Discussions

Daily Agenda

- Instrument Codes and symbols: The primary purpose of using codes and symbols is to enable the various Instrument functions required in a process to be clearly and concisely represented on Process Flow Diagrams (PFD) and on Pipeline and Instrumentation Drawings (P&ID). They also indicate which process parameter is being measured, the relative locations of the measure¬ment and control devices and the permissible limits applicable to certain variable process conditions.

- Instrument tang number: Usually identified by 3 codes (location number code – Function letter code – Serial number code)

- Location Number code: Indicates the specific process unit in which the instrument is installed.

- Function letter code: Indicates the property or process variable being measured or controlled.

- Serial number code: Identifies the specific instrument and therefore prevents confusion when there are several instruments in a single process unit, each having the same function letter code.

- Annunciators: Alarm system designed for altering the process operator for abnormal operation conditions, thus enabling corrective action to be taken.

- Process Block Diagram: The process block diagram is the simplest diagram that indicates the main process and utility systems.

- Process Flow Diagrams (PFD): A PFD is a simplified flow diagram of either a single process unit, a utility unit, a complete process module or offsite product storage or loading system. PFD provides a preliminary understanding of the process system indicating only the main items of equipment, the main pipelines and the essential instruments

- Piping and Instrumentation Drawing (P&ID): P&ID is a detailed flow diagram of different operating facilities connected together. P&ID typically provide detailed information about plant equipment, instruments and control devices, operating data…etc.

- Control Loop Diagram: This Diagram is used to express control philosophy. Loop diagram must show the components and accessories of the instrument loop. This diagram is used for construction purpose, inspection, commissioning and start-up, maintenance, modification, reconstruction and documentation.

- Cause and Effect Charts: Cause and Effect charts are logic matrices, which list the detectable problems (causes) against the automatic control reactions (effects) taken to safeguard the process and process area. The causes are described by the problem (event), the location or equipment involved (process component) and the device detecting the problem (normally the instrument tag no.). The effects explain the action taken, the location/equipment affected (process component) and which shutdown devices are activated (by tag no.).

- Functional Logic Diagram: The Logic Diagram is mainly a summarisation of the Shutdown philosophy of a specific equipment or plant in the form of symbols.

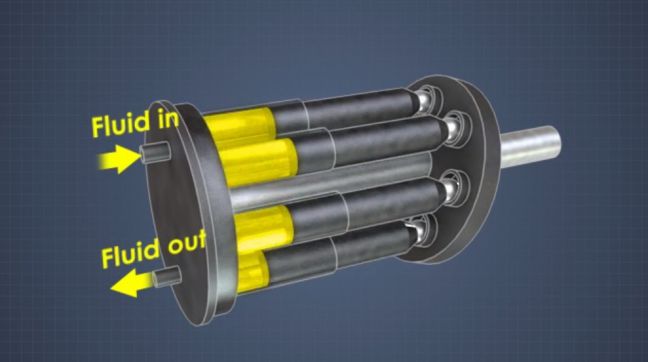

- Instruments Hook-Up Diagram: Shows how the instruments and their fittings of a loop are assembled to form a working unit. List and identify the material required.

Accreditation

BTS attendance certificate will be issued to all attendees completing minimum of 80% of the total course duration.

Quick Enquiry

Request Info

Related Courses

Your Growth, Our Mission