Course Details

Your Growth, Our Mission

Course Description

The Training Course Will Highlight ?

Training Objective

Target Audience

This course is recommended for anyone involved with the Failure Analysis Inspection, maintenance and troubleshooting of Steam Turbines. Such as Mechanical Maintenance Engineers, Under Development Engineers, Mechanical Maintenance Supervisors &Technicians and Operation Engineer

Training Methods

Daily Agenda

Module (01) Steam Turbine Classification

- Axial Flow Turbines

- Radial Flow Turbines

- Back Pressure Turbines

- Extraction Turbines

- Condensing Turbines

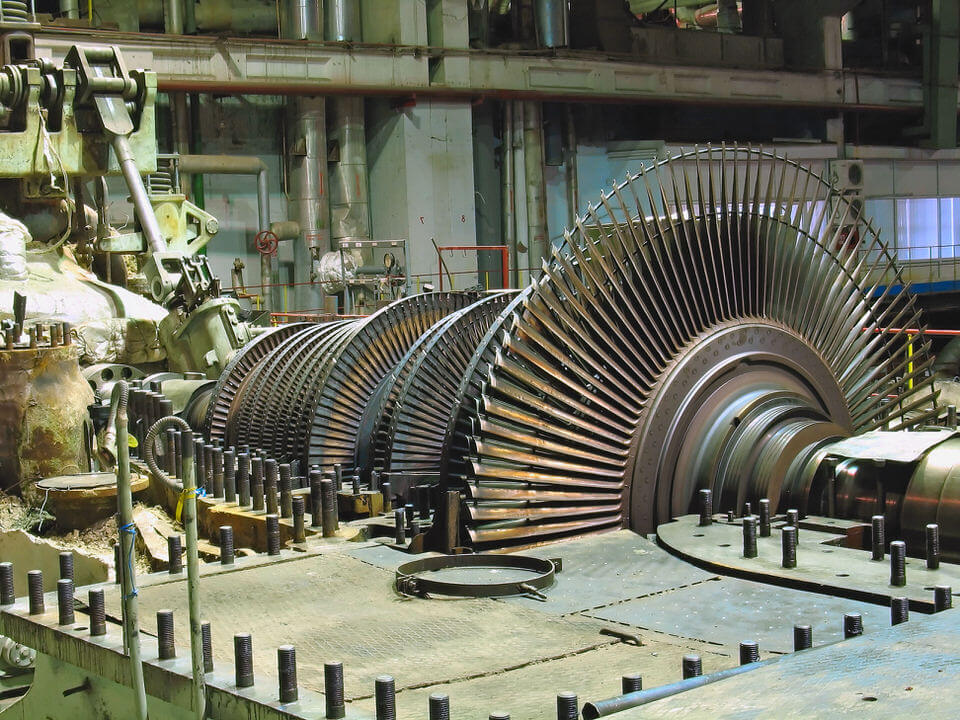

Module (02) Steam Turbine Components

- Rotors

- Casings

- Rotating Blades

- Stationary Blades (Diaphragms) and Labyrinth

- Steam Turbine Bearings

- Turbine Glands and Gland Seal Flow Diagrams

Module (03) Lubrication and Control Oil System

- Oil Flow Diagrams

- Oil Pumps

- Oil Vapor Extraction Unit

- Shaft Lifting Oil System

- Main Oil Tank

- Hydraulic Accumulator

- Oil Heat Exchanger

- Oil Purification Stations

Module (04) Condenser

- Purpose of the Condenser

- Condenser Types

- Operating Principle of Condenser

- Condenser Cleaning Units

- Leakage Detection

Module (05) Steam Turbine valves and Governor

- Steam Turbine Governor

- Mechanical

- Hydraulic

- Electronic

- Steam Turbine Valves

- Steam Turbine Turning Gear

- Steam Turbine Flanges Heating System

- Steam Turbine Steam traps System

Module (06) Steam Turbine Control Systems

- Purposes of Steam Turbine Control

- Control of Steam Turbines

- Speed Control - Admission Pressure Control

- Control Methods for Steam Admission

- Steam Turbine Control Loop

Module (07) Steam Turbine Performance

- Power Plant Efficiency

- Thermos dynamic efficiency

- Feed water heating

- Air Heating

- super heater – Reheat Steam

- Condenser Performance

- Temperature and speed increases

- Condition monitoring turbine warm up

- Operator responsibilities during speed rising process

- Increasing and Decreasing load

Module (08) Steam Turbine Protection

- Turbine Manual Trips

- Over Speed Trip Mechanisms

- Lubricating Oil Protection System

- Journal Bearing Protection System

- Thrust Bearing Protection System

- Low Vacuum Protective System

- Vibration Protection System

- Firs Fighting System

Summarize Lesson Learnt

Evaluation / Examination

- Course Closeout

Accreditation

BTS attendance certificate will be issued to all attendees completing minimum of 80% of the total course duration.

Quick Enquiry

Request Info

Related Courses

Your Growth, Our Mission