Course Details

Your Growth, Our Mission

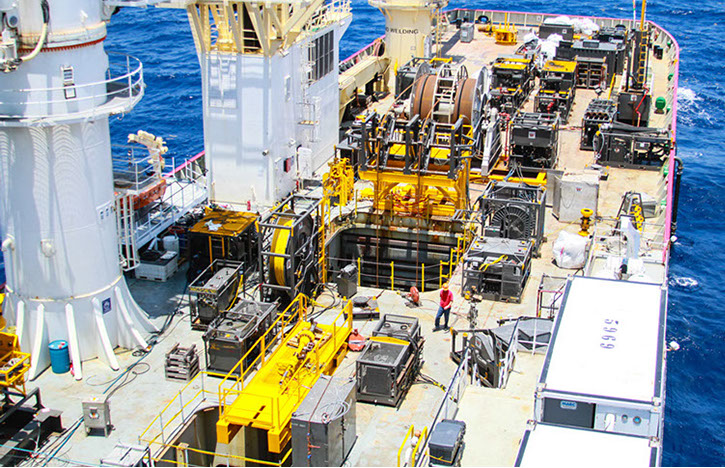

Course Description

The Training Course Will Highlight ?

The course will feature:

- Completion Equipment

- Wireline Equipment

- Coiled Tubing Equipment

- Hydraulic Workover (Snubbing) equipment

- Pressure Control Management

- Barrier Principles

- Well Information

- Shut-in Procedures

- Pressure Control Methods

- Problems

Training Objective

By the end of this course, delegates will be able to:

- Identify the accountabilities of program signatories

- Know the causes and effects of unplanned inflow

- Recognize potential causes of losses

- Define gas migration

- Describe how the lubricates and bleed methods can be applied

- Detect a possible blockage anywhere in the well

Target Audience

Drilling Engineers, Senior Drilling Engineers, Drilling Supervisors, Drilling Superintendents, Petroleum Engineers, Completion Engineers, Tool Pushers, Reservoir and Senior Reservoir Engineers, Geologists, Production and Completion Engineers, Foremen, Workover Engineers, Petroleum Engineers, Completion Engineers, Tool Pushers, Reservoir and Senior Industry Personnel, Lifting Personnel, Maintenance Engineers, Technologists, Mud Engineers, Well Site Supervisors, Drilling Contractors, Drilling Supervisors, Completion Engineers, Completion Supervisors, Drilling Managers, Drilling Technical Support Personnel, Trainee Drillers, Rig Engineers, Industry Personnel, Completion engineers, Production staff, Petroleum engineers, Other technical staff that need an understanding and an appreciation of HSE aspects of well drilling, completion, work-over and well intervention, Roustabouts, Roughnecks, Derrickmen, Assistant Drillers and leading drilling personnel offshore, Employees and managers in drilling service Companies, Management of drilling rigs and drilling installations, Engineering personnel for design and modification of drilling facilities

Training Methods

This interactive Training will be highly interactive, with opportunities to advance your opinions and ideas and will include;

- Lectures

- Workshop & Work Presentation

- Case Studies and Practical Exercise

- Videos and General Discussions

Daily Agenda

- Well control event

- Pre-operation planning

- Hydrostatic pressure

- Formation pressure

- Fracture pressure

- Primary and secondary well control

- Pressure control equipment

- Introduction to barriers

- Risk management

- Causes to unplanned well inflow

- Loss of hydrostatic pressure

- Swap and surge effects

- Unplanned warning flow warning signs and indicators

- Calculation systems

- Well integrity testing

- Influx characteristics and behaviors

- Shut-in procedure and interpretation

- Influx migration

- Kill methods principles

- Normal and reverse circulation

- Bullheading

- Lubricate and bleed methods

- Contingency planning

- Maximum pressures

- Bottom hole pressure effect

- Blockage in the well

- Blowout preventer

- BOP stack configuration

- Ram type preventers

- Blind/shear ram

- Annular preventers

- Barrier management

- Inflow testing

- Completion equipment

- Rig/up rig/down

- Annulus pressure monitoring

- Coiled tubing equipment

- Hydraulic work over (snubbing) operations

- Seals and sealing elements

- Valves

- Wireline operations

- Surface equipment

- Slick line/ braided line sheer seal BOP

- Wireline BOP pressure retention

- Managing a leak or malfunction in the surface

- Critical operation procedure

Accreditation

BTS attendance certificate will be issued to all attendees completing minimum of 80% of the total course duration.

Quick Enquiry

Request Info

Related Courses

Your Growth, Our Mission