Course Details

Your Growth, Our Mission

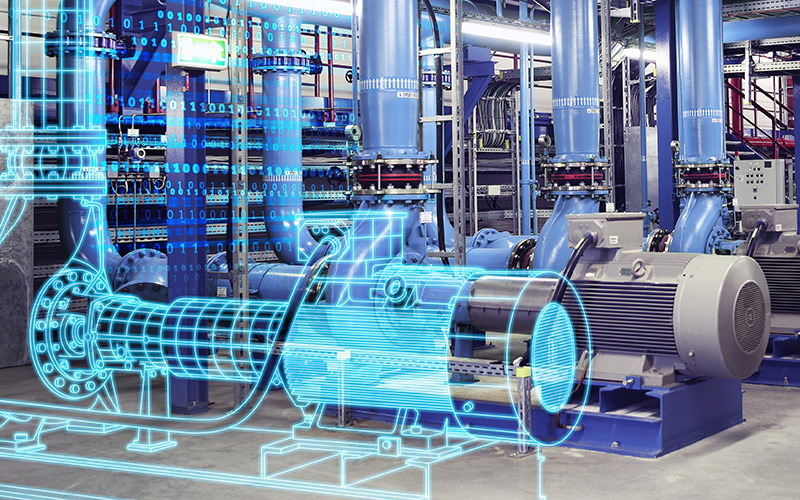

Course Description

This course provides attendees the training needed to extend their knowledge of machinery diagnostic techniques and rotor dynamics as applied to rotating machinery. In particular, they will learn the use of synchronous and non-synchronous perturbation testing to evaluate complex dynamic stiffness in rotor/bearing/seal systems, including its modal parameters, and see how to bring analytical model response predictions in closer agreement with actual machine data. The class also examines how rotor torsional modes are coupled with lateral modes, and how that information may be used for early detection of shaft crack.

The Training Course Will Highlight ?

Attendees will learn how to model machinery operation and malfunctions in fundamental terms, preparing them to better identify and understand machinery problems in the field.

Training Objective

Attendees will learn how to model machinery operation and malfunctions in fundamental terms, preparing them to better identify and understand machinery problems in the field.

Target Audience

- Engineers desiring to advance their machinery vibration diagnostics skills

- Engineers involved in the design, acceptance testing, and maintenance of rotating machinery

- Post-graduate engineering attendees

- Academic researchers and professors involved in rotor dynamics

Training Methods

Daily Agenda

Day 1

- Introduction to Rotating Machinery Dynamics

- Steady-State and Startup/Shutdown Plot Review

- Basic Rotor Modeling

- Stiffness Concepts and Calculations

- Critical Speed Maps

- Modal Mass Definition and Calculation

- Model Rotor Kit and Predict Resonance Frequency

- Fundamental Synchronous Rotor Response

- Synchronous Dynamic Stiffness Testing

Day 2

- Workshop: Single-Plane Balancing

- How to Handle Anisotropic Systems

- Multi-Plane Balancing (Static and Coupled Balancing)

- Polar Plot Balancing

- Static and Couple Balancing

- Workshop: Multi-Plane Balancing

Day 3

- Preload Forces on Machinery

- Internal Preloads (including Gears and Pumps)

- External Preloads (including Misalignment)

- Dynamic Stiffness Parameters – No synchronous Perturbation

- Workshop: Identify Dynamic Stiffness Parameters Using

No synchronous Perturbation Data

Day 4

- Fluid-Induced Instabilities of Rotors: Whirl and Whip – Summary of Results Instability Source Location

- Workshop: Diagnose and Control Fluid-Induced Instabilities

- Rotor to Stationary Part Rubbing

- Case History: Steam Turbine Rub During Startup and Generator

Seal Rub Showing Slowly Changing Amplitude and Phase Lag

- Workshop: Diagnose and Identify Partial Radial Rotor-to-Stator Rubs

Day 5

- Detection of Cracked Shafts

- Case History: Reactor Recirculation Pump with a Shaft Crack

- Compressors – Mechanical and Aerodynamic Design Surge and

Stall Malfunctions

- Seminar Summary – Questions and Answers

Accreditation

BTS attendance certificate will be issued to all attendees completing minimum of 80% of the total course duration.

Quick Enquiry

Request Info

Related Courses

Your Growth, Our Mission