Course Details

Your Growth, Our Mission

Course Description

This course provides a thorough understanding of steam power plants, gas turbines, co-generation, combined cycle plants, wind and solar power generating plants. Each of the components such as compressors, gas and steam turbines, heat recovery steam generators, deaerators, condensers, lubricating systems, instrumentation, control systems, transformers, and generators are covered in detail. The design, selection considerations, operation, maintenance, pay-back period, and economics of co-generation plants and combined cycles as well as emission limits, reliability, monitoring and governing systems will also be covered thoroughly. All the significant improvements that were made to co-generation, combined cycles plants, wind and solar power generating plants during the last two decades will also be explained.

The Training Course Will Highlight ?

Training Objective

Target Audience

Power Generation Engineers, Power Generation Technicians, Power Generation Operators, Maintenance personnel , Other technical individuals

Training Methods

This interactive Training will be highly interactive, with opportunities to advance your opinions and ideas and will include;

- Lectures

- Workshop & Work Presentation

- Case Studies and Practical Exercise

- Videos and General Discussions

Daily Agenda

Gas Turbines

- Gas Turbine Fundamentals

- Modes of operation

- Typical process systems that form part of plant

- Key transducers to monitor operation

- Events/alarms, etc.

- Overview of Gas Turbines

- Gas Turbine Design

- Gas Turbine Calculations

- Gas Turbine Compressors

- Gas Turbine Maintenance

- Overview of the equipment

- Dynamic Compressors Technology

- Compressors Auxiliaries

- Off-Design Performance

- Stall, and Surge

- Centrifugal Compressors – Components

- Performance Characteristics

- Balancing, Surge Prevention Systems and Testing

- Dynamic Compressors Performance

- Compressor Seal Systems

- Dry Seals

- Advanced Sealing Mechanisms and Magnetic Bearings

Gas Turbine Components and Auxiliaries

- Gas Turbine Combustors

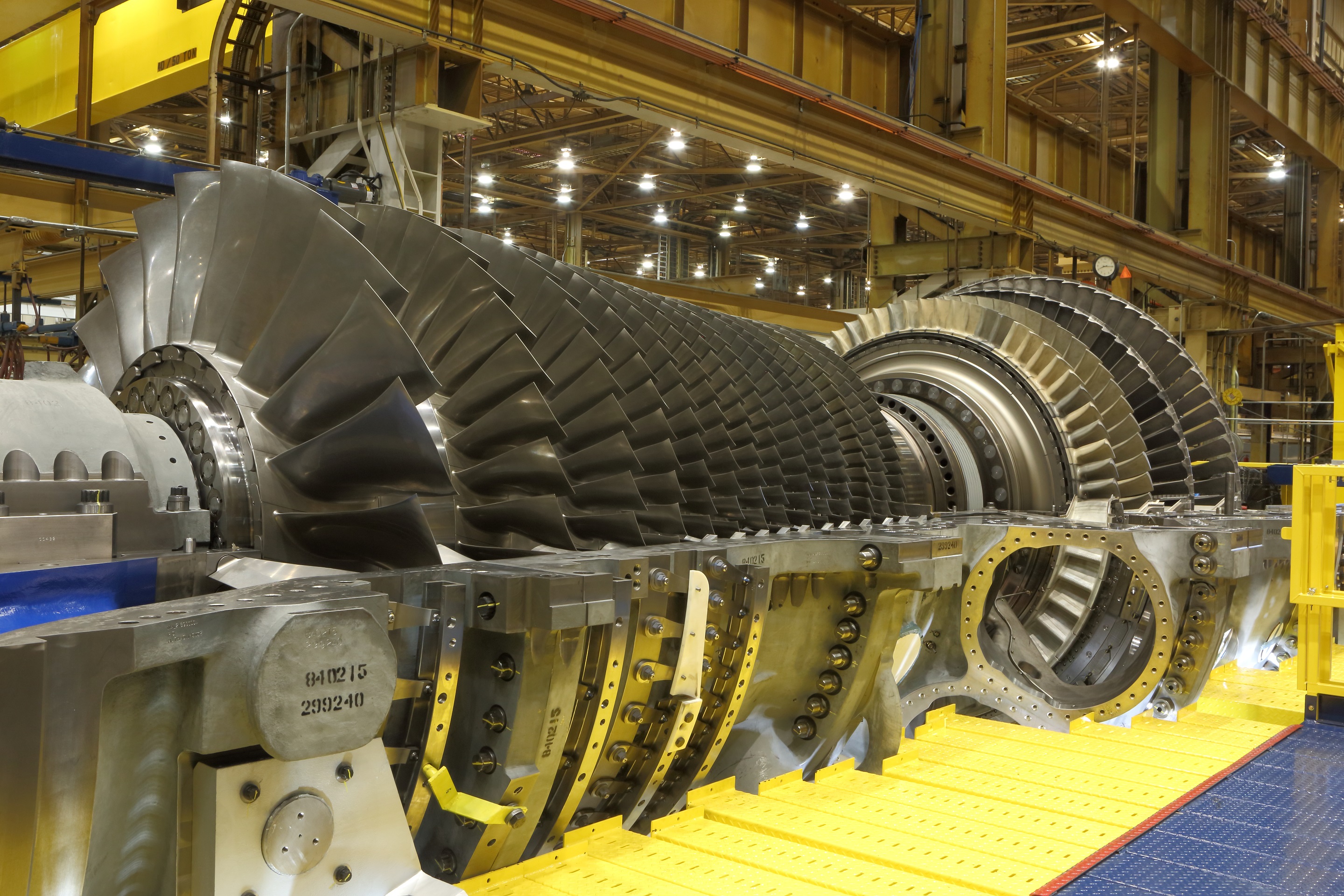

- Axial-Flow Turbines

- Gas Turbine Materials

- Gas Turbine Lubrication and Fuel Systems

- Gas Turbine Bearing and Seals

- Gas Turbine Instrumentation and Control

- Gas Turbine Performance Characteristics

- Gas Turbine Operating and Maintenance Considerations

- Gas Turbine Emission Guidelines and Control Systems

Steam Power Plants

- Review of Thermodynamics Principles

- Steam Power Plants

- Steam Generators

- Steam Turbines

- Re-heaters

- Condensers

- Feed-water Heaters

- Efficiency and Heat Rate

- Supercritical Plants

- Co-generation Plants

- Arrangement of Co-generation plants

- Economics

Steam Generators and Steam Turbines

- The Fire-Tube Boiler

- The Water-Tube Boiler

- The Steam Drum

- Super heaters and Re-heaters

- Once-Through Boilers

- Economizers

- Fans

- The Stack

- Steam Generator Control

- Feed-water and Drum-Level Control

- Steam-Pressure Control

- Steam-Temperature Control

- Mechanisms of Energy Conversion

- Turbine components

- Rotating and Stationary blades

- Thrust bearings

- Labyrinth seals

- Turbine controls

- Testing of Turbine blades

- Quality Assurance of Turbine Generator

- Assembly and testing of turbine components

Steam Turbines and Auxiliaries

- Turbine Types

- Compound Turbines

- Turbine Control Systems

- Maintenance

- Steam Generators

- Heat Exchangers and Condensers

- Power Station Performance Monitoring

- The Turbine Governing System

- Steam Chests and Valves

- Turbine Protective Devices

- Turbine Instrumentation

- Lubrication Systems

- Gland Sealing System

- Frequently Asked Questions about Turbine-Generator Balancing

- Vibration Analysis and Maintenance

- Features Enhancing the Reliability and Maintainability of Steam Turbines

Combined Cycles

- Combined Cycles

- Integrated Gasification Combined Cycles

- Single-Shaft Combined Cycle Power Generating Plants

- Turbine Selection for Combined Cycle Power Systems

- Absorption Chillers

- Selection of the Best Power Enhancement Option for Combined Cycle Plants

Transformers

- Fundamentals of Electric Systems

- Introduction to Machinery Principles

- Transformers

- Transformers Components and Maintenance

Generators

Steam Turbine Maintenance

Power Station Performance Monitoring

Accreditation

BTS attendance certificate will be issued to all attendees completing a minimum of 80% of the total course duration.

Quick Enquiry

Request Info

Related Courses

Your Growth, Our Mission