Course Details

Your Growth, Our Mission

Course Description

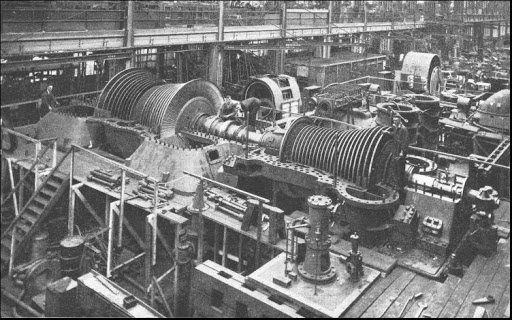

There are two main types of steam turbine, impulse and reaction. The principles are different, but the processes construction are somewhat similar. In either type steam is caused to impinge on blades carried on a rotating part. The high speeds and stresses involved necessitate great strength and accuracy of manufacture. Since Sir Charles A. Parsons produced in 1884 his first practicable steam turbine, enormous advances have been made with this form of prime mover. The generation of electricity on a rapidly growing scale all over the world during recent years has led to the almost universal use of steam turbines for the driving of electric generators where water power is unobtainable. The objective of this module is to present the major features of steam turbine construction, and support systems.

The Training Course Will Highlight ?

Training Objective

Target Audience

Electrical Engineers, Power Generation Engineers, Power System Protection Engineers, Process Control Engineers & Personnel, Electrical and Instrumentation Technicians & Design Engineers, Maintenance Technicians & Supervisors, Plant Operators & Technicians, Oil & Gas Industry Personnel

Training Methods

This interactive Training will be highly interactive, with opportunities to advance your opinions and ideas and will include;

- Lectures

- Workshop & Work Presentation

- Case Studies and Practical Exercise

- Videos and General Discussions

Daily Agenda

- Major components of the steam turbine

- Conversion of heat energy (in steam) to rotating mechanical energy

- Stationary and moving blades

- Impulse and reaction blading

- Steam conditions at turbine exhaust

- Increase in specific volume of steam at low pressure

- Typical multi-cylinder arrangements

- Location of support bearings

- Function of the thrust bearing

- Allowance for expansion of rotor and casing

- Rotor construction, disks and blades

- Diaphragms and fixed blades

- Turbine assembly

- Function of shaft gland seals

- Gland steam leak-off and supply system

- Interstage seals

- Typical lube oil circulation system

- Need for continuous lube oil cooling and cleaning

- Standby oil pumps A.C. and D.C

- Hydraulic oil application

- Combined lube and hydraulic oil system

- Function of the condenser and location

- Condenser mechanical arrangements

- Fouling of condenser tubes and tube plate

- Water box siphon system

- Effect of air leakage into the condenser

- Removal of air and incondensable gases from the condenser by vacuum equipment

- Function of the steam ejector for start-up and on-line operation

Accreditation

BTS attendance certificate will be issued to all attendees completing a minimum of 80% of the total course duration.

Quick Enquiry

Request Info

Related Courses

Your Growth, Our Mission